Discover the Ultimate Guide to SMC Cylinder Catalog: Enhance Your Automation Efficiency Today!

In today's rapidly evolving industrial landscape, maximizing automation efficiency is paramount for staying competitive. The SMC cylinder catalog emerges as a vital resource, offering an extensive range of pneumatic and automation solutions tailored to meet diverse operational needs. According to a report by MarketsandMarkets, the global automation market is projected to reach USD 296.70 billion by 2026, underscoring the importance of adopting advanced technologies. The comprehensive selection within the SMC cylinder catalog not only enhances productivity but also minimizes downtime, ensuring streamlined operations.

With features designed for durability, precision, and versatility, utilizing the right components can significantly improve overall system performance. This guide aims to illuminate the essential elements of the SMC cylinder catalog, empowering businesses to refine their automation strategies and optimize efficiency like never before.

Understanding the Importance of SMC Cylinder Selection for Automation

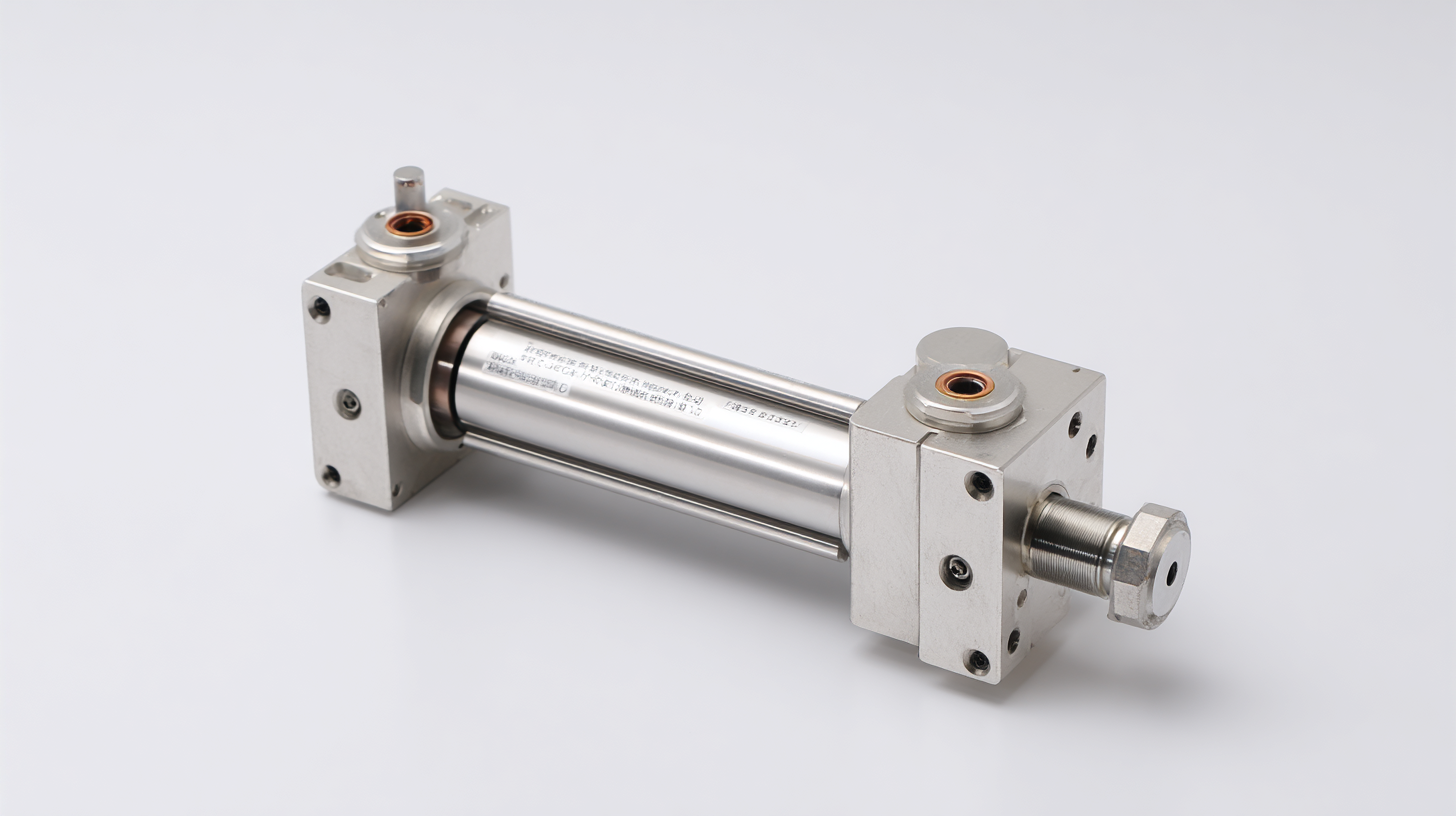

When it comes to enhancing automation efficiency, selecting the right SMC cylinders is crucial. The varying demands of industries such as mining necessitate cylinders that can withstand harsh conditions while providing reliable performance. These heavy-duty automation components must be able to operate with precision under significant stress, making informed selection vital for operational success. A thorough understanding of the specific requirements for each application ensures that the right cylinder is integrated into the automation process, leading to enhanced productivity and reliability.

Moreover, the shift towards energy-efficient manufacturing is becoming increasingly significant in sectors like food production. The right cylinder selection directly influences the energy consumption of machinery, contributing to cost savings and sustainability. Manufacturers are urged to consider the long-term benefits of optimal cylinder choices, as they not only improve machine performance but also align with the growing emphasis on eco-friendly practices. By prioritizing effective cylinder selection, companies can not only enhance their operational efficiency but also meet the modern industry's shift towards sustainability.

Discover the Ultimate Guide to SMC Cylinder Catalog: Enhance Your Automation Efficiency Today!

| Cylinder Type | Bore Size (mm) | Stroke Length (mm) | Working Pressure (MPa) | Action Type |

|---|---|---|---|---|

| Double Acting | 32 | 100 | 1.0 | Standard |

| Single Acting | 50 | 150 | 0.8 | Spring Return |

| Compact | 16 | 50 | 1.2 | Double Acting |

| Rodless | 20 | 200 | 0.9 | Double Acting |

| Mini | 10 | 25 | 0.7 | Single Acting |

Key Features and Specifications of SMC Cylinders to Consider

The SMC cylinder catalog is an essential resource for enhancing automation efficiency in various applications. When selecting SMC cylinders, it’s crucial to consider key features and specifications that impact performance. For instance, the type of cylinder, its bore size, and stroke length can significantly influence the overall efficiency of your automation system. Furthermore, factors such as operating pressure range and response time should also be evaluated to ensure optimal performance tailored to your specific needs.

Tips to enhance your choice process include reviewing the operating environment of your cylinders; ensure that materials used can withstand the conditions they will face. Additionally, thinking about future scalability is important—invest in cylinders that provide versatility for potential upgrades or modifications. Finally, keep an eye out for the latest technologies in cylinder design that may offer improved energy efficiency or reduced maintenance needs, further streamlining your automation processes.

SMC Cylinder Features Comparison

How to Compare Different SMC Cylinder Models for Optimal Performance

When selecting an SMC cylinder, understanding the various models available is crucial for maximizing performance in your automation systems. Each SMC cylinder model has its unique specifications and features designed for specific applications. Start by analyzing key attributes such as bore size, stroke length, and actuator type. This will help you identify which model aligns best with your operational needs.

Tips for Comparison: One effective way to compare different models is by creating a comparison chart that not only lists the specifications but also includes performance data from real applications. Engaging with the manufacturer’s technical resources or consulting with experts can provide additional insights into how specific models perform under various conditions.

Don't overlook factors such as environmental resistance and maintenance ease when comparing models. Cylinders used in harsh environments may require special materials or coatings, enhancing durability and reducing downtime. Use this essential information to guide your decision-making process, ensuring you choose the right SMC cylinder to elevate your automation efficiency.

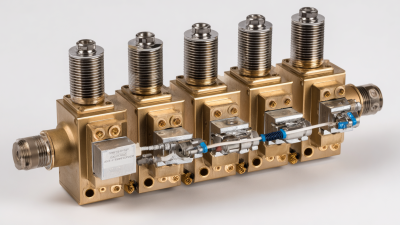

Integrating SMC Cylinders into Your Existing Automation Systems

Integrating SMC cylinders into your existing automation systems can significantly enhance operational efficiency. SMC, a leader in pneumatic and automation technology, offers a comprehensive range of cylinders designed to streamline production processes. According to a report by the International Federation of Robotics, implementing advanced automation technologies can increase productivity by up to 30%, resulting in reduced cycle times and improved product quality. When integrating SMC cylinders, it’s essential to assess your current system's compatibility, as this will determine the level of enhancement attainable.

Tips: When selecting SMC cylinders for integration, consider factors such as operating pressure, stroke length, and mounting options to ensure optimal performance. Additionally, utilizing SMC's online configurator can save time and help you find the right specifications tailored to your project needs. Another key aspect is to invest in training for your team, as proficient operation of these systems can lead to minimal downtime and maximized efficiency.

By optimizing the integration process, companies can experience a seamless transition to enhanced automation systems. A study by McKinsey & Company found that companies actively investing in automation technologies saw a 20-25% increase in their overall operational efficiency within the first year of implementation. Therefore, making strategic choices in the selection and integration of SMC cylinders can yield substantial long-term benefits for your automation initiatives.

Resources for Maintaining and Troubleshooting SMC Cylinders in the Field

Maintaining and troubleshooting SMC cylinders in the field is critical for ensuring optimal performance and longevity of automation systems. According to a report by the International Society of Automation, improper maintenance can lead to a 20% drop in efficiency, resulting in significant downtime and increased operational costs. Regular maintenance practices, such as inspecting seals, lubricating moving parts, and checking for air leaks, can prevent such inefficiencies and extend the lifecycle of the cylinders.

Moreover, in addressing common troubleshooting issues, having access to comprehensive resources is essential. Industry studies show that more than 30% of automation failures are attributed to pneumatic components like cylinders. Detailed catalogs and technical documentation can help engineers quickly identify issues, enabling them to implement effective solutions promptly. For instance, understanding the correlation between cylinder wear rates and expected performance metrics allows for better decision-making concerning part replacements, ultimately enhancing production efficiency. By leveraging such resources, professionals can ensure that SMC cylinders operate at peak performance, contributing to the overall success of automation efforts.

Related Posts

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

-

Unlocking the Future: How Automation Solutions Are Transforming Everyday Life

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries