Top Machine Vision System Applications for Industry and Innovation?

In recent years, the machine vision system has transformed industries worldwide. This technology aids in quality control, automation, and data collection. Reports from MarketsandMarkets indicate that the global machine vision market is expected to exceed $15 billion by 2026. Such growth highlights its relevance across various sectors.

Machine vision systems employ advanced algorithms and imaging technologies. They ensure precision in manufacturing processes. For instance, in the automotive industry, these systems can identify defects in real time. However, some companies still encounter challenges in integrating machine vision. This gap raises questions about implementation strategies and workforce readiness.

Moreover, the technology’s role in innovation is undeniable. Vision-guided robots enhance production efficiency. Industry leaders see a potential 30% increase in output with effective machine vision deployment. Yet, companies must reflect on their current capabilities. The right balance between technology and human expertise is crucial for future success.

Top Machine Vision System Applications in Manufacturing Processes

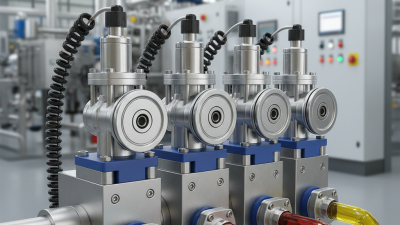

Machine vision systems play a crucial role in modern manufacturing processes. These systems use cameras and advanced algorithms to inspect products on the assembly line. They can identify defects or inconsistencies with remarkable speed and precision. This automation leads to improved efficiency in production.

In one application, a machine vision system checks the quality of assembled parts. It captures high-resolution images and analyzes them in real time. If a defect is detected, the system can stop the line immediately. This quick response minimizes waste and reduces costs. However, implementing these systems is not without challenges. Calibration can be a complex task, and lighting conditions must be ideal for optimal performance.

Another interesting application involves barcode reading. Machine vision systems can scan products quickly as they move along the conveyor belt. This ensures accurate inventory tracking. Errors in barcode recognition may occur, leading to potential miscounts. Continuous adjustments and employee training are essential to overcome such issues. Each step in integrating these technologies requires careful consideration and ongoing reflection.

Impact of Machine Vision on Quality Control and Inspection Standards

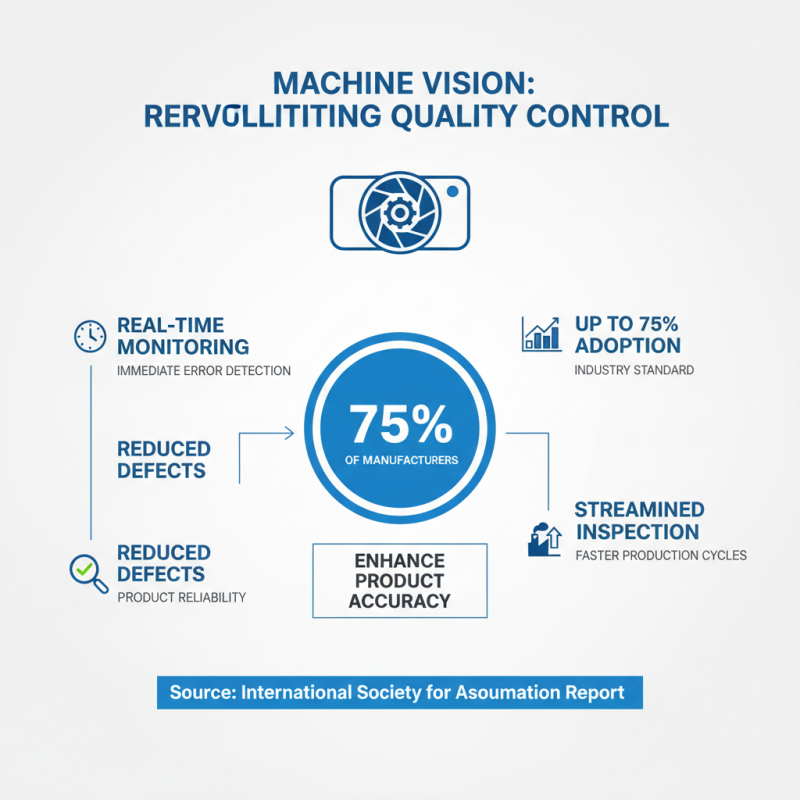

Machine vision systems have revolutionized quality control and inspection standards across industries. A recent report by the International Society for Automation notes that up to 75% of manufacturers now use machine vision to enhance product accuracy. This technology allows for real-time monitoring, which significantly reduces errors and defects.

Implementing these systems can bring challenges. Many organizations encounter integration issues with existing processes. Additionally, not all machine vision systems are created equal. Variability in image quality can lead to inconsistent inspection results. Investing in proper training is essential for staff to utilize these systems effectively.

**Tip:** Regularly review and update inspection processes to adapt to new technologies.

Moreover, machine vision ensures compliance with industry standards. It streamlines workflows and improves overall efficiency. According to a study by the Automation Federation, companies that adopt machine vision can see up to a 30% increase in productivity. However, adapting to this technology takes time. Continuous evaluation means organizations must stay alert for potential shortcomings in their systems.

**Tip:** Encourage open communication among team members to address technology limitations.

Advancements in Machine Vision for Autonomous Robotics and Automation

Machine vision systems are revolutionizing autonomous robotics and automation. According to a recent report by MarketsandMarkets, the machine vision market is expected to reach $19.2 billion by 2026. This growth highlights the increasing demand for automation across various industries. Robotics and machine vision are working together to enhance precision and efficiency in manufacturing processes.

One significant advancement is in quality control. Machine vision can detect flaws in products much faster than human inspectors. A study showed that companies using machine vision systems reported a 30% reduction in defects. However, not all systems perform perfectly. Environmental factors like lighting can impact accuracy. This poses challenges that need addressing.

Moreover, the integration of machine vision in robotics enhances navigation and object recognition. Advances in deep learning algorithms are improving these capabilities. The potential for error does exist, especially when systems encounter unforeseen variables. Continuous improvement and adaptation are necessary to optimize performance in diverse environments. This is a non-stop journey toward innovation and efficiency.

Machine Vision Systems in Medical Imaging and Healthcare Innovations

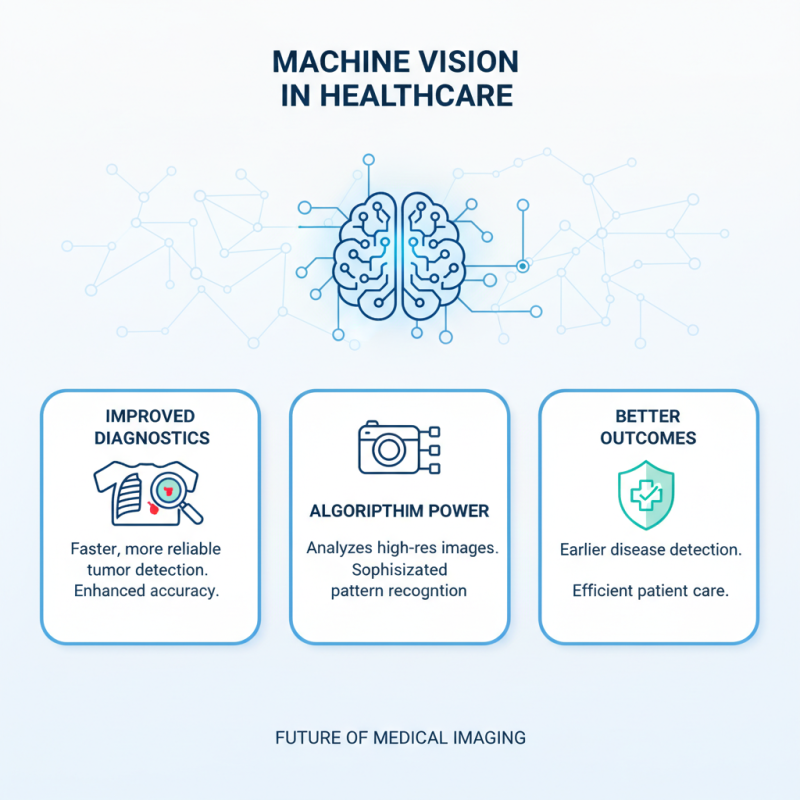

In recent years, machine vision systems have made significant advancements in the medical imaging and healthcare sectors. These systems enhance diagnostic accuracy and speed. They utilize high-resolution cameras and sophisticated algorithms to analyze medical images. This leads to better patient outcomes and more efficient healthcare processes. For instance, detecting tumors through imaging becomes quicker and more reliable.

One tip for healthcare providers is to invest in training. Staff should understand both the technology and its potential limitations. Machine vision is not infallible. Errors can occur, and human oversight is crucial. Adding a layer of review can prevent misdiagnoses. Simple adjustments can lead to significant improvements in patient care.

Moreover, the integration of machine vision in healthcare prompts ethical considerations. Privacy and data security remain paramount. Patients must trust that their medical images are handled responsibly. Continuous evaluations of these systems will help address potential risks and enhance their benefits. Effective machine vision systems can revolutionize healthcare, but constant reflection on their implementation is essential.

Emerging Trends in Machine Vision Technologies Supporting Industry 4.0

Emerging trends in machine vision technologies are shaping the landscape of Industry 4.0. According to a report by Markets and Markets, the global machine vision market is expected to reach $22 billion by 2024. This growth is driven by advancements in deep learning and artificial intelligence. These technologies enable machines to analyze images with greater accuracy and speed.

Automation remains a key focus. Factories equipped with machine vision systems can significantly reduce error rates. In fact, studies suggest automated systems can achieve up to 99% accuracy in quality control. However, challenges persist. Many industries face integration issues with legacy systems. Ensuring compatibility can slow down implementation.

Another vital aspect is data usage. The integration of machine vision systems generates massive amounts of data. Proper analysis of this data is crucial but often overlooked. Companies must refine their data processing techniques. Insufficient data management can lead to missed opportunities and inefficiencies. Investing in training for staff could enhance outcomes.

Top Machine Vision System Applications for Industry and Innovation

| Application | Industry | Technology Used | Benefits | Emerging Trends |

|---|---|---|---|---|

| Quality Control | Manufacturing | Image Processing, AI | Increased accuracy, Reduced waste | Integration with IoT |

| Automated Inspection | Electronics | 3D Imaging, Deep Learning | Real-time feedback, High throughput | Smart Cameras |

| Robotic Guidance | Logistics | Computer Vision, Sensors | Improved navigation, Efficiency | Autonomous Systems |

| Surface Inspection | Textiles | Optical Inspection, AI | Consistency, Defect detection | Advanced Imaging Techniques |

| Facial Recognition | Security | Machine Learning, Image Analysis | Enhanced security, Identity verification | Biometric Systems |

Related Posts

-

2025 Top 5 Machine Vision Systems Revolutionizing Industry Automation

-

Top 5 Benefits of Using Pneumatic Operated Valves in Industrial Applications

-

How to Choose the Right Norgren Valves for Your Industrial Applications 2025

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Top 10 Tips for Choosing the Right Air Solenoid for Your Project

-

How to Navigate the SMC Cylinder Catalog for Efficient Selection and Use

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries