How to Select the Right Automatic Valve for Your Application?

Selecting the right automatic valve for your application can be challenging. Experts emphasize the importance of understanding specific needs. Jane Smith, a leading specialist in the automatic valve industry, once said, "The key to success is matching the valve with your operational requirements."

In many industries, choosing the correct automatic valve impacts efficiency and safety. However, many users struggle with the various types and specifications. It's easy to overlook factors like pressure, temperature, and flow rate. This often leads to costly mistakes.

Furthermore, assessing long-term costs and maintenance needs is essential. Many focus solely on upfront costs. This approach can lead to larger expenditures down the line. So, taking time to research and reflect on your specific application could save you significant resources and headaches.

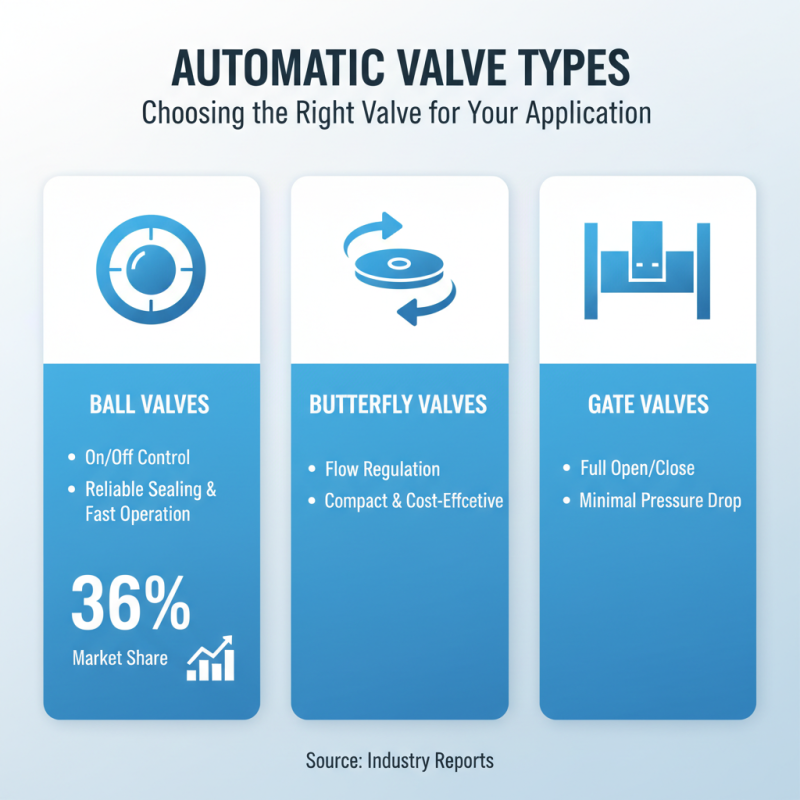

Understanding the Different Types of Automatic Valves

When selecting an automatic valve, understanding the different types is crucial. Common types include ball valves, butterfly valves, and gate valves. Each serves unique applications. For instance, ball valves are often used for on-off control. They provide reliable sealing and fast operation. According to industry reports, ball valves account for 36% of the market share in the automatic valve segment.

Butterfly valves are another significant type. They are lightweight and suitable for large volumes of fluid. They are generally used in water supply and wastewater treatment. Reports indicate these valves are projected to grow at a CAGR of 5.8% over the next five years. Despite their advantages, they may not offer the best sealing performance compared to other options.

Gate valves are used primarily for isolation, not throttling. They can handle high-pressure applications effectively. However, they might struggle with flow control. Many industries overlook the importance of flow characteristics in their selection process. Existing data suggests that improper valve choice leads to up to a 15% increase in maintenance costs. Evaluating the specific needs of your system is essential before making a choice.

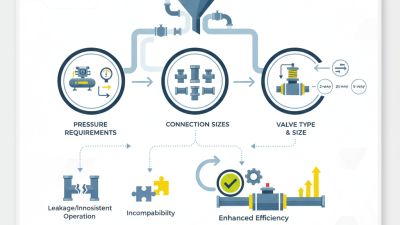

Key Considerations for Selecting an Automatic Valve

Choosing the right automatic valve for your application requires careful consideration. One key factor is the medium flowing through the valve. Different fluids, such as water or chemicals, have varying properties. Ensure the valve material is compatible with the medium to prevent degradation. This is often overlooked, leading to future issues.

Another important aspect is the valve size. A valve that is too small can restrict flow, while one that is too large may result in pressure loss. Measure your piping accurately. It’s crucial to account for the pipe diameter and flow rate. A mismatch here will lead to inefficiency and possible system failures.

Lastly, power requirements can affect your choice. Do you need a pneumatic, electric, or hydraulic actuator? Evaluate the power availability in your facility. If the selection is wrong, it can create operational hiccups. It's also important to consider the environment. Extreme temperatures or corrosive conditions may limit your options. Reflecting on these details will guide you toward a suitable valve selection, avoiding potential pitfalls in the long run.

Evaluating the Application Requirements and Environment

When selecting an automatic valve, understanding application requirements is crucial. The valve must align with fluid types, pressure conditions, and temperature ranges. According to a report by Flow Control, 50% of valve failures stem from improper selection. This highlights the importance of careful assessment.

Consider the environment where the valve will operate. Harsh conditions, such as high humidity or corrosive substances, demand specialized materials. For instance, valves exposed to extreme temperatures may require specific seals and coatings. A study by the International Society of Automation shows that 30% of valve malfunctions relate to inappropriate material choices. This indicates a need for thorough environmental evaluations.

Designing for maintenance accessibility is often overlooked. Poorly placed valves can complicate repairs and increase downtime. A recent survey revealed that 40% of maintenance delays involve valve accessibility issues. This points to the necessity of considering not just the valve but its location and installation during the selection process. Assessing these factors thoroughly can prevent future complications.

How to Select the Right Automatic Valve for Your Application?

| Application Area | Valve Type | Size | Pressure Rating (psi) | Temperature Range (°F) | Control Type |

|---|---|---|---|---|---|

| Water Treatment | Ball Valve | 2" | 150 | 32 - 150 | Electric |

| Oil & Gas | Gate Valve | 6" | 600 | -20 - 250 | Pneumatic |

| Chemical Processing | Butterfly Valve | 4" | 300 | -40 - 200 | Electric |

| HVAC Systems | Ball Valve | 1.5" | 150 | 32 - 180 | Manual |

| Food & Beverage | Sanitary Valve | 3" | 125 | -20 - 130 | Electric |

Comparing Valve Materials and Designs for Durability

When selecting an automatic valve, the choice of materials and design significantly impacts performance. Common materials include stainless steel, brass, and plastic. Stainless steel offers excellent corrosion resistance. However, it can be heavy and costly. Brass is durable and often used in smaller applications but may corrode in harsh environments. Plastic valves are lightweight and cost-effective, but they may not withstand high pressures or temperatures.

Design also plays a crucial role in durability. A unique valve design may enhance flow efficiency, yet it can complicate maintenance. Some designs incorporate multiple sealing points for better leak prevention. However, this can also present a challenge if a seal fails. Understanding the application’s specific demands is key. Will the valve be exposed to extreme conditions or corrosive substances?

Reflections on past selections often reveal missed opportunities for optimization. Learning from these experiences can lead to better choices. Take time to evaluate the long-term implications of material and design. Durability is not just about the immediate cost; it’s about performance over time. Ask critical questions to ensure the chosen valve meets all requirements.

Installation and Maintenance Factors for Automatic Valves

When selecting automatic valves, installation and maintenance are crucial. Proper installation ensures efficiency. Misalignment can cause leaks. Also, consider the environment where the valve will be installed. Extreme temperatures may affect performance.

Regular maintenance is essential for longevity. Check for wear and tear periodically. Lubricate moving parts to prevent rust. Always replace worn seals. This step avoids larger problems later.

Here are some tips:

- Keep a maintenance log.

- Use quality tools during installation.

- Monitor valve performance regularly.

These actions lead to improved reliability. Remember, overlooking details may result in higher costs. It’s important to commit to ongoing care.

Related Posts

-

Why Choosing High Pressure Pneumatic Valves is Essential for Efficient System Performance

-

What is a Pneumatic Control Valve and How Does It Work?

-

How to Choose the Right Pneumatic Solenoid Valve for Your Application?

-

Top 10 High Pressure Pneumatic Valve Uses and Benefits?

-

2026 Top Trends in Machine Vision Systems for Industrial Automation?

-

How to Choose the Right Pneumatic Air Cylinder for Your Industrial Applications

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries