What is a Pneumatic Control Valve and How Does It Work?

A pneumatic control valve plays a crucial role in various industrial applications. It regulates the flow of air or gas using pressure. This valve is essential for maintaining the proper functioning of numerous systems.

Understanding how a pneumatic control valve operates can seem daunting. However, the basics are quite straightforward. This valve uses air pressure to open and close, controlling flow effectively. Proper installation and maintenance are key to its efficiency. Yet, many overlook these aspects.

In real-world applications, a pneumatic control valve can face wear and tear. For instance, regular vibrations can affect its performance. Users may find themselves questioning its reliability. Thus, awareness and knowledge of this component are vital in ensuring an optimal setup.

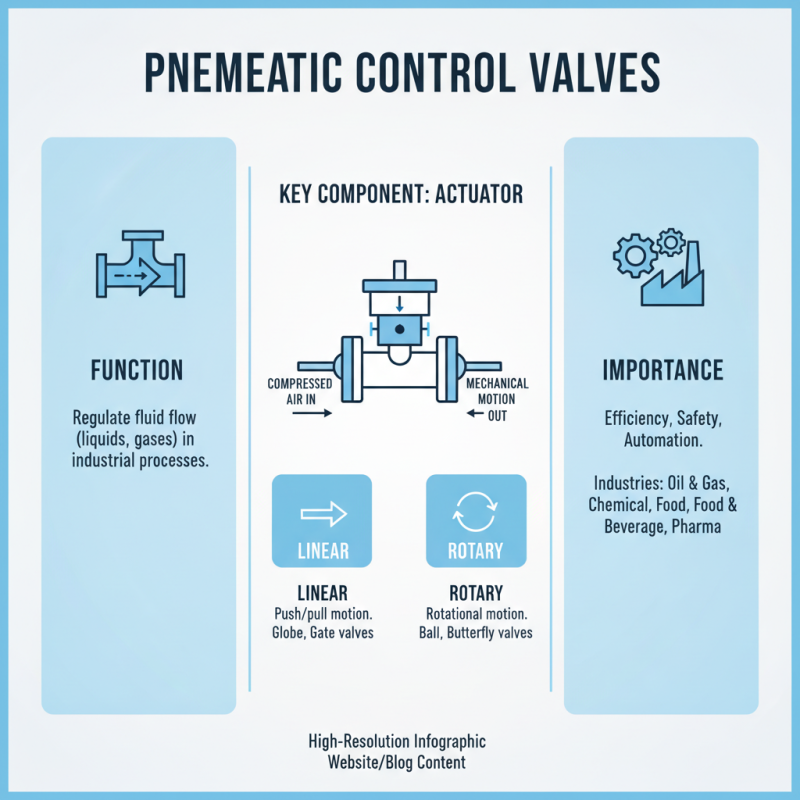

Definition of a Pneumatic Control Valve

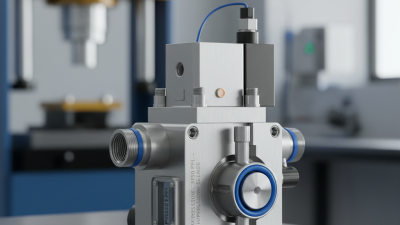

A pneumatic control valve is a device that uses compressed air to control fluid flow. These valves operate by regulating pressure and actuation. Typically, they consist of a cylindrical casing with a movable diaphragm or piston. When air pressure is applied, the diaphragm moves, opening or closing the valve. This action regulates the flow of liquids or gases in various processes. According to a market report, the global pneumatic valve market is expected to reach $8.3 billion by 2025, driven by industrial automation and safety standards.

Pneumatic control valves are vital in many industries, such as manufacturing, oil and gas, and water treatment. They provide precise control over process conditions. By adjusting the air pressure, operators can fine-tune the flow rates. This contributes to efficiency and safety. Reports indicate that improper valve selection can lead to up to 30% energy losses in a system.

Tips: Regular maintenance of pneumatic valves is crucial. Check for leaks and calibration regularly. Small adjustments can lead to better performance. Always consult application data sheets to ensure optimal valve selection. Understand the specific requirements of your system. This can help avoid costly mistakes and improve overall operation.

Key Components of a Pneumatic Control Valve

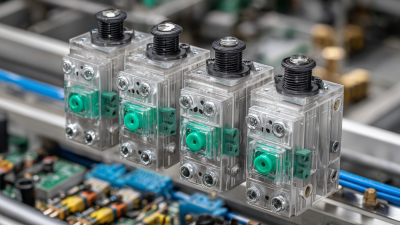

Pneumatic control valves play a crucial role in various applications. Their design includes several key components that ensure efficient operation. The actuator is vital. It converts energy from compressed air into motion, controlling the valve's opening and closing. It can be linear or rotary, affecting how fluid flows through the system.

Another important component is the valve body. This is where the media flows. Different shapes and sizes allow for various flow paths. Sometimes, the selection of valve body material can be a point of reflection. The choice may impact durability and performance under different conditions.

Additionally, the positioning sensing device monitors the valve's performance. It helps control the motion accurately. If misaligned, it could lead to inefficiencies in the system. Therefore, regular maintenance and calibration are just as crucial as choosing the right components. A small oversight here can disrupt an entire process.

How Pneumatic Control Valves Operate

Pneumatic control valves are essential for managing the flow of fluids in various industrial applications. They function by using compressed air to control the opening and closing of the valve. This operation involves a diaphragm or piston that responds to air pressure changes. Interestingly, a report by the International Society for Automation (ISA) shows that proper valve control can enhance system efficiency by up to 25%.

When dealing with pneumatic control valves, it’s vital to maintain regular inspections. Dirt or damage can compromise functionality. A study by the American Society of Mechanical Engineers (ASME) indicates that neglecting maintenance can lead to a 15% increase in operational costs due to energy inefficiencies. Keeping valves clean can prevent these unnecessary expenses.

**Tip**: Regularly check for leaks in your pneumatic system. Even a small leak can affect performance. Ensuring proper alignment of the valve can also improve responsiveness.

Pneumatic systems have limitations. For instance, their performance may decrease in extreme temperatures. Operating outside recommended ranges can lead to failures. In fact, a survey in the industry highlights that nearly 30% of malfunctioning valves were due to thermal issues. Understanding these nuances can lead to better decision-making in the selection of control valves.

Common Applications of Pneumatic Control Valves

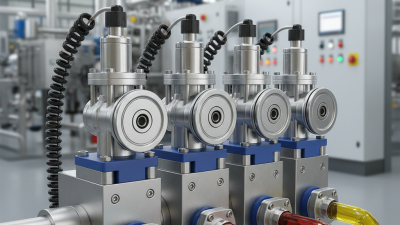

Pneumatic control valves play a significant role across various industries. They help in regulating the flow of air and gases in many applications. According to a report by MarketsandMarkets, the pneumatic valve market is projected to reach $4.4 billion by 2025, growing at a CAGR of 5.2%. This growth reflects the increasing demand in sectors like manufacturing and automotive.

In the manufacturing sector, pneumatic valves are often used in assembly lines. They control the movements of actuators, improving efficiency. For instance, a typical assembly line can complete tasks 30% faster with pneumatic control. In the oil and gas industry, these valves handle the flow of gases. They ensure proper pressure is maintained in pipelines. However, frequent leaks can occur, leading to environmental concerns and the need for regular maintenance.

Pneumatic control valves are also common in food processing. They help manage the flow of ingredients, ensuring consistency in production. However, strict hygiene standards must be met. Any failure can result in contamination. Despite their advantages, the industry faces challenges. Improving reliability while managing costs remains a focus for engineers and companies alike.

What is a Pneumatic Control Valve and How Does It Work? - Common Applications of Pneumatic Control Valves

| Application | Function | Working Principle | Benefits |

|---|---|---|---|

| Manufacturing | Control the flow of compressed air for machinery operation | Regulates airflow based on a signal from the control system | Increases efficiency and reduces manual control |

| Automotive | Control air pressure in pneumatic systems for diagnostics | Adjusts pressure levels using a control signal from the vehicle’s computer | Enhances safety and performance optimization |

| HVAC Systems | Regulate air flow and pressure in heating and cooling systems | Operates via thermostatic control or manual inputs | Improves energy efficiency and indoor air quality |

| Food Processing | Control dosing of ingredients and packaging processes | Uses sensors to monitor and adjust flow rates | Ensures precision and reduces waste |

Advantages of Using Pneumatic Control Valves

Pneumatic control valves are widely used in various industries. They manage the flow of air or gas to control machines or processes. One significant advantage of pneumatic control valves is their rapid responsiveness. They can open or close quickly, improving operational efficiency.

Another benefit is their simplicity. Pneumatic systems are often easier to maintain than hydraulic systems. They require less complex handling and can be more cost-effective. Additionally, these valves can function in extreme conditions. They perform well in high or low temperatures, making them versatile.

However, they are not without challenges. Sometimes, air leaks can occur, reducing efficiency. Operators must regularly check for these leaks. Moreover, the need for a compressed air supply can limit their use in certain situations. Understanding both the benefits and limitations is essential for effective applications.

Related Posts

-

Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

-

Why Choosing High Pressure Pneumatic Valves is Essential for Efficient System Performance

-

Top 7 Best Pneumatic Control Valves for Enhanced Industrial Performance

-

Top 5 Benefits of Using Pneumatic Operated Valves in Industrial Applications

-

Top 10 Benefits of Using Pneumatic Operated Valves in Industry

-

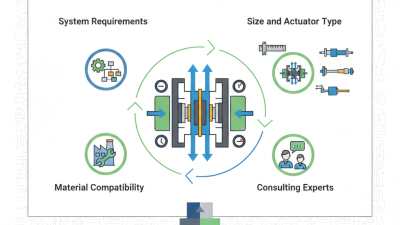

2026 How to Choose the Right Pneumatic Operated Valve for Your System?

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries