How to Choose Norgren Valves for Your Applications?

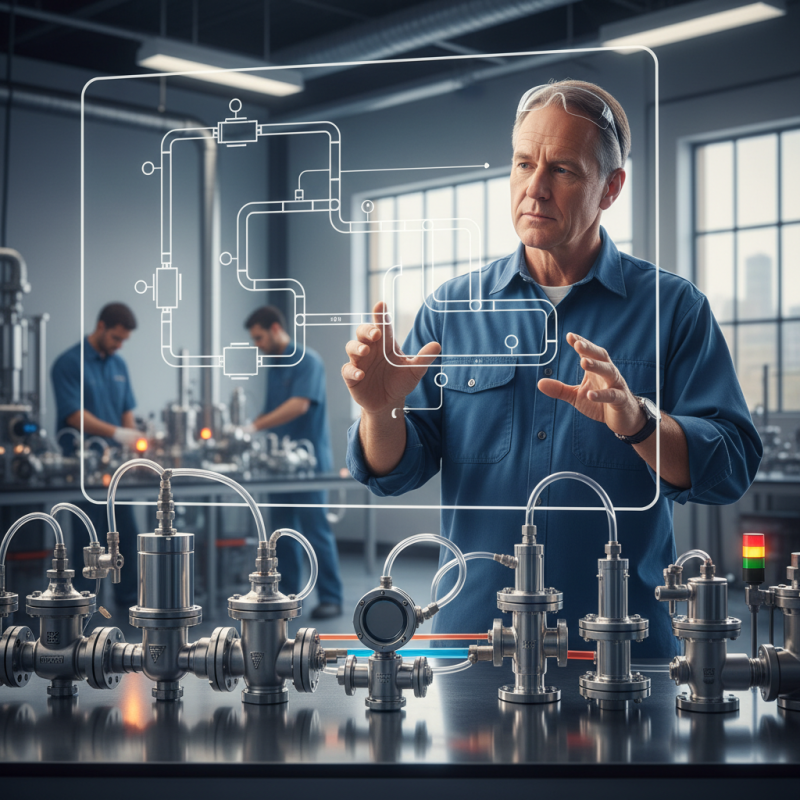

Choosing the right Norgren valves for your applications can significantly impact system performance. John Smith, a renowned expert in fluid control systems, once said, “Selecting the correct valve is critical for efficiency.” This emphasizes the importance of making informed decisions in valve selection.

Understanding your specific application requirements is essential. Factors like pressure, flow rate, and media type can influence your choice. A misstep in selecting Norgren valves could lead to operational inefficiencies. For instance, using the wrong valve size might cause leaks or reduced performance, which can be costly.

Furthermore, the variety in Norgren's offerings can be daunting. Each valve type serves different purposes, and selecting the wrong one may require time-consuming adjustments or replacements. It's crucial to analyze your needs thoroughly. Reflecting on past decisions can provide insight. Have you always chosen wisely? It's a question worth pondering as you navigate the selection process.

Understanding the Basics of Norgren Valves and Their Applications

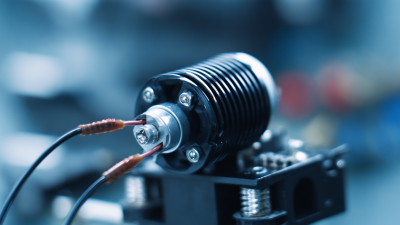

Norgren valves are widely used in various industries. They play a crucial role in controlling fluid power systems. These valves manage air, gas, and fluid flow. Understanding their functions can help you choose the right type for your application.

Different valves serve different purposes. Some are designed for high-pressure environments, while others work well in low-pressure contexts. They can vary in size and operating mechanisms. Choosing a valve isn't always straightforward. Many factors come into play, like the specific needs of your system. Performance and reliability are key. If you choose poorly, efficiency may drop.

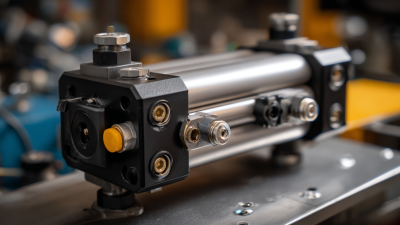

In applications requiring precision, actuation becomes vital. Valves need to respond quickly and accurately. Yet, some users overlook these details. Mistakes can lead to downtime or equipment failure. It is essential to evaluate all aspects carefully. User feedback may provide insights that specifications alone cannot reveal. This kind of reflection can improve decision-making.

Identifying Key Specifications for Selecting Norgren Valves

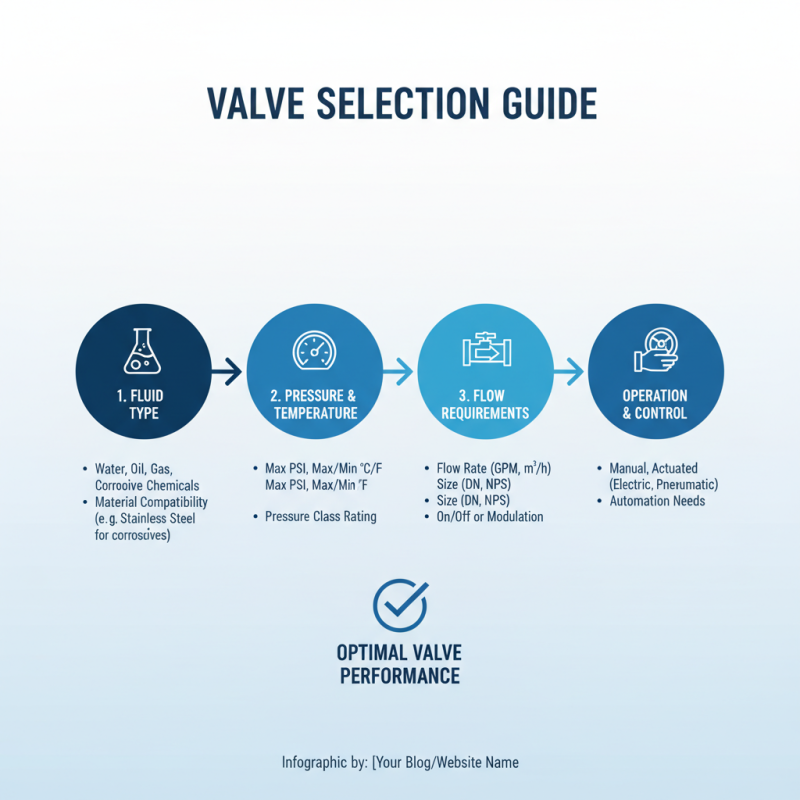

Choosing the right valves for your applications involves understanding key specifications. Start by identifying the type of fluid being used. Different fluids can require different materials. For example, corrosive fluids may need resistant materials. This decision affects valve longevity and reliability.

Consider the pressure and temperature ratings of the valves as well. Valves must operate effectively within these limits. Operating outside the specified range is risky. It can lead to failure or costly downtime. Always verify these ratings against your system’s requirements.

Tips: Ensure you have accurate measurements of your system’s pressure and temperature. An incorrect reading could lead to poor choice. Also, think about the environment. Is it humid or dusty? These factors can impact valve performance.

Lastly, check the flow rate requirements. Each application will have different demands. An oversized valve may cause issues, just as an undersized one would. Evaluating flow is crucial, but it’s often overlooked. Don’t just go for the familiar sizes; analyze your needs closely.

Evaluating Performance Factors in Norgren Valve Selection

When selecting valves for applications, performance factors are crucial. Pressure rating is one important aspect. It dictates how much stress a valve can handle. Consider the maximum pressure you expect in your system. Underestimating this can lead to valve failure.

Another factor is flow rate. This determines how quickly the fluid moves through the valve. Using a valve that restricts flow can affect efficiency. Sometimes, users choose a valve without fully understanding the impact on their system. It’s worth testing flow rates in real conditions, not just theoretical values.

Response time is also essential. In some applications, a quick response is necessary. A delayed response can cause issues, especially in automation. Look at the actuator type and its speed. Are you certain it meets your needs? Perform trials to ensure the response aligns with your operational requirements. Small changes in response can have significant effects. These performance factors require careful consideration during selection.

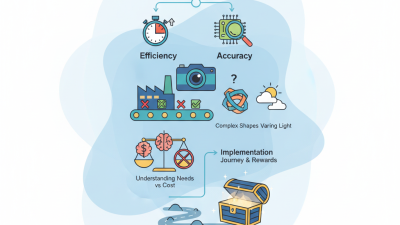

Performance Factors in Norgren Valve Selection

This chart illustrates various performance factors that are critical in selecting valves for specific applications. Each factor is quantified to help evaluate their importance in the decision-making process.

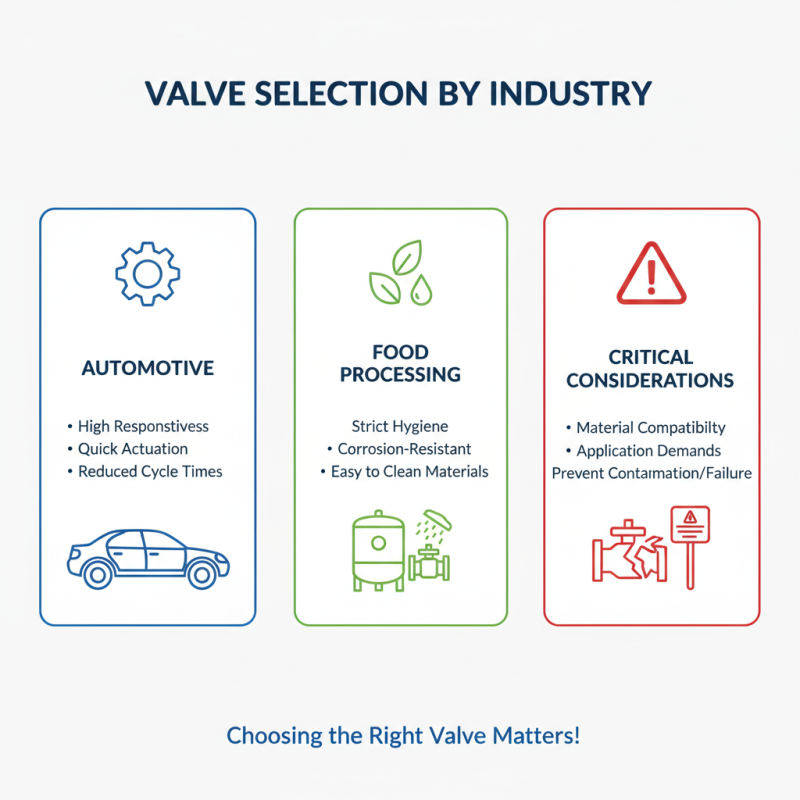

Comparing Norgren Valve Types for Specific Industry Needs

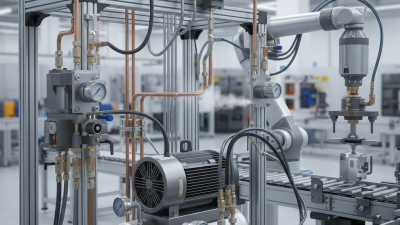

When selecting valves for specific industries, it’s crucial to understand the unique demands of each application. For example, in the automotive sector, high responsiveness is vital. A valve with quick actuation reduces cycle times. It ensures smoother operations. Similarly, food processing facilities require valves that meet strict hygiene standards. These valves must be corrosion-resistant and easy to clean. Failing to choose the right materials can lead to serious issues.

In pneumatic systems, the type of valve directly impacts efficiency. Solenoid valves are often preferred for automated tasks. Their ability to control flow rapidly enhances overall performance. On the other hand, manual valves may suit simpler applications well. They offer reliability but require more hands-on attention. Factoring in the environment is also essential. Extreme temperatures or exposure to chemicals can compromise valve function. Reflect on how these factors resonate with your needs. Would a standard choice suffice, or does your application demand something more specialized?

Ensuring Compatibility with Existing Systems and Components

Choosing the right valves for your system can be challenging. Compatibility is crucial. A mismatched valve can cause performance issues. So, ensure that the specifications align with existing systems. Consider factors like pressure ratings, flow capacities, and voltage types.

Measuring the dimensions of installed components is essential. Space constraints can affect valve selection. Small discrepancies might not seem significant, but they can lead to installation difficulties. Also, double-check the connection types. Even the smallest variation can create leaks or inefficiencies.

Sometimes, manufacturers provide guidelines for compatibility. However, these may not cover all scenarios. Understanding your system's unique requirements takes time. Don't rush this step. Examine your current setup closely. This will help prevent costly mistakes in the future. Compatibility is more than just numbers; it's about ensuring everything works harmoniously.

Related Posts

-

How to Choose the Right Norgren Valves for Your Industrial Applications 2025

-

How to Choose the Right Air Cylinder for Your Application

-

Top 2025 Pneumatic Actuator Innovations for Enhanced Automation Solutions

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Why Choose a Machine Vision System for Your Industrial Applications?

-

What is a Pneumatic System and How Does It Work?

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries