2026 How to Choose the Right Pneumatic Operated Valve for Your System?

When selecting the right pneumatic operated valve for your system, understanding your specific needs is crucial. Industry expert John Smith, a veteran in fluid dynamics, once stated, "The right valve can make or break an entire operation." This highlights the importance of making a thoughtful choice.

Pneumatic operated valves control airflow and pressure. Their performance directly impacts system efficiency. A poor selection can lead to leaks, increased costs, and downtime. Often, companies overlook the material compatibility, size, and actuator type, which can lead to significant problems later.

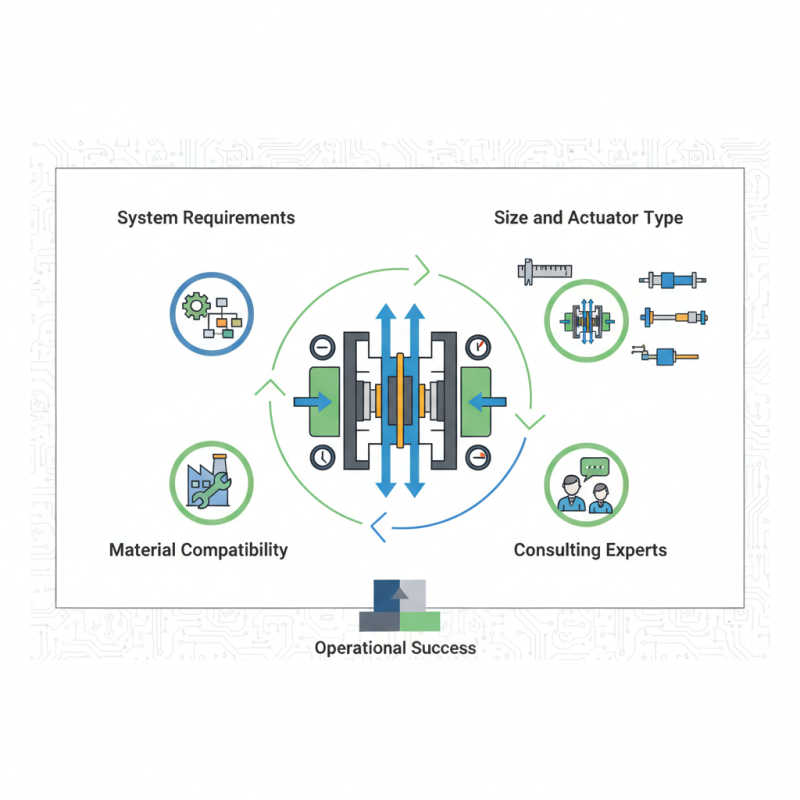

Finding the best pneumatic operated valve requires careful consideration. Evaluate your system’s requirements and consult with experts if needed. Each application has unique challenges. A tailored approach will yield better results. Don't underestimate the value of this decision. The right valve is more than just a component; it’s a cornerstone of operational success.

Overview of Pneumatic Operated Valves and Their Applications

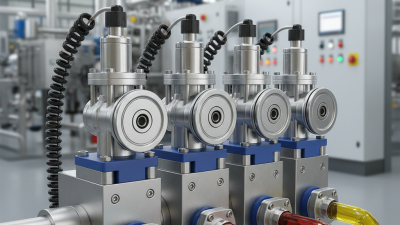

Pneumatic operated valves are crucial in various industries. They control the flow of air and gases in a system. These valves use compressed air to function. Their design allows for quick opening and closing. This speed can enhance process efficiency significantly. They are found in manufacturing, HVAC, and chemical processing.

Different types of pneumatic valves serve specific functions. For instance, spool valves direct flow between different paths. Butterfly valves provide a compact solution for flow control. Choosing the right type can be challenging. Often, users overlook the importance of pressure ratings. Also, compatibility with system materials can be a concern.

Applications for these valves are vast. In many cases, systems require precise control to avoid leaks. They can also handle varying temperatures and mediums. Regular maintenance is key to prolonging their life. Without proper care, they may underperform over time. Each application may present unique challenges. Careful assessment is essential before installation.

Key Factors Influencing the Selection of Pneumatic Valves

Selecting the right pneumatic operated valve for your system is critical. Several key factors significantly influence this choice. Understanding the specific application is fundamental. For instance, the medium flowing through the valve—gas or liquid—makes a difference. Each type has unique requirements.

Another important factor is the valve size. You must consider flow rates and pressure drops. Over or undersizing can lead to inefficiencies. Also, the actuator type should align with your control system's needs. Electric, spring-return, or double-acting actuators each have pros and cons.

Material compatibility is often overlooked. The valve must withstand the operating environment. Corrosion, temperature extremes, and physical pressure all play a role. Failing to address these can result in premature failure. These considerations prompt further reflection on the valve's lifecycle and maintenance needs. Choosing a pneumatic valve isn’t always straightforward.

2026 How to Choose the Right Pneumatic Operated Valve for Your System?

| Selection Criteria | Description | Importance Level |

|---|---|---|

| Size and Dimensions | Determine the valve size based on pipeline size and flow requirements. | High |

| Material Compatibility | Ensure materials withstand the media and environment for longevity. | High |

| Pressure Rating | Select valves that can handle the system pressure efficiently. | Critical |

| Actuation Type | Choose between double-acting or spring return actuators. | Medium |

| Response Time | Evaluate how quickly the valve responds to control signals. | High |

| Operating Temperature | Ensure the valve can operate effectively within desired temperature ranges. | Medium |

| Flow Direction | Confirm that the valve supports the correct flow direction in the system. | High |

| Maintenance Needs | Assess the ease of maintenance and parts availability. | Medium |

Comparison of Common Types of Pneumatic Operated Valves

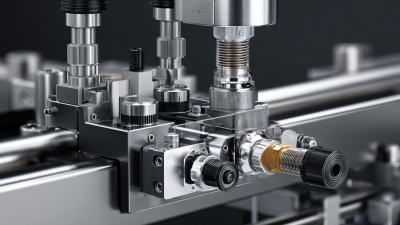

Choosing the right pneumatic-operated valve requires understanding the common types available. Two popular options are diaphragm valves and ball valves.

Diaphragm valves offer excellent sealing and are great for handling corrosive fluids. They are typically lightweight and simple to maintain. Ball valves, on the other hand, provide quick on-off control. They are often preferred for their straight-through flow design.

Tips: Consider the medium you will be controlling. Verify that the valve material matches the fluid type. This reduces maintenance issues down the line.

Another type is the globe valve. Globe valves are suitable for throttling applications. They have a higher pressure drop but allow for better flow regulation. They can be useful in systems requiring fine adjustments.

Understanding your system’s requirements can help you choose wisely. Don’t overlook installation constraints. Ensure there is enough space for the valve to function correctly. Mistakes in this area can lead to operational failures.

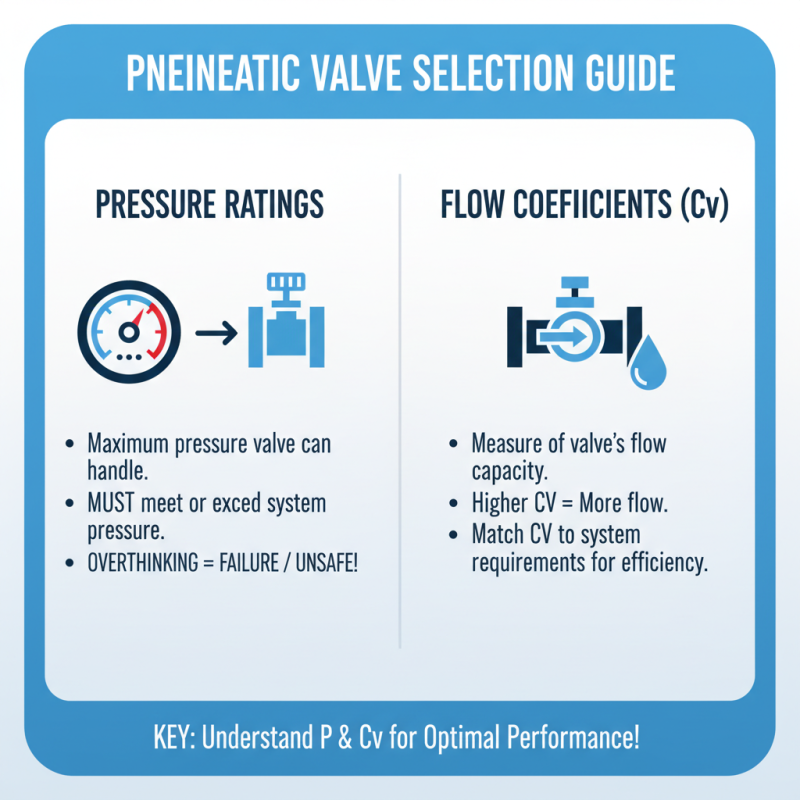

Understanding Pressure Ratings and Flow Coefficients in Valves

When selecting a pneumatic operated valve, understanding pressure ratings and flow coefficients is crucial. Pressure ratings indicate the maximum pressure a valve can handle safely. It’s important to choose a valve that meets or exceeds your system's pressure needs. Overlooking this detail can lead to valve failure or unsafe situations.

Flow coefficients, often denoted as Cv values, help determine how much fluid a valve can pass. A higher Cv means better flow capacity. Know your system's requirements. If your demand changes, you might need a valve with a different Cv. Ensuring compatibility is vital for efficiency.

Tips: Always calculate the pressures and flow requirements early in your design process. Don’t rush this step. Rushing can lead to costly mistakes. Make a checklist for your needs. Consider the environments where the valve will operate. Think about temperature extremes and potential corrosive substances. Reflect on all aspects of your application. Choose wisely.

Industry Standards and Best Practices for Pneumatic Valve Selection

When selecting a pneumatic valve, industry standards play a vital role. The valve's function must align with system requirements. It is crucial to understand the environment where the valve will operate. Factors such as temperature, pressure, and media compatibility matter greatly. Various standards exist, like those from ANSI and ISO, which provide guidelines on materials and performance.

Best practices in pneumatic valve selection involve careful consideration. Valve specifications should detail flow rates and sizes. Dimensions are key; a poorly sized valve can lead to inefficiencies. Also, consider the actuator type. Different actuators offer various response times and power considerations. Sometimes, users overlook these details, leading to unexpected issues.

Additionally, proper installation and maintenance are critical. These aspects are often neglected, affecting system performance. An improperly installed valve can malfunction, causing downtime. Regular inspection and testing can prevent future headaches. Remember to gather feedback from operators too. Their insights can highlight potential improvements in the selection process.

Related Posts

-

Top 10 Benefits of Using Pneumatic Operated Valves in Industry

-

Top 5 Benefits of Using Pneumatic Operated Valves in Industrial Applications

-

Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

-

Top 7 Best Pneumatic Control Valves for Enhanced Industrial Performance

-

What is a High Pressure Pneumatic Valve and How Does It Work

-

Exploring the Future of Automation: The Essential Role of Pneumatic Components in Modern Industries

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries