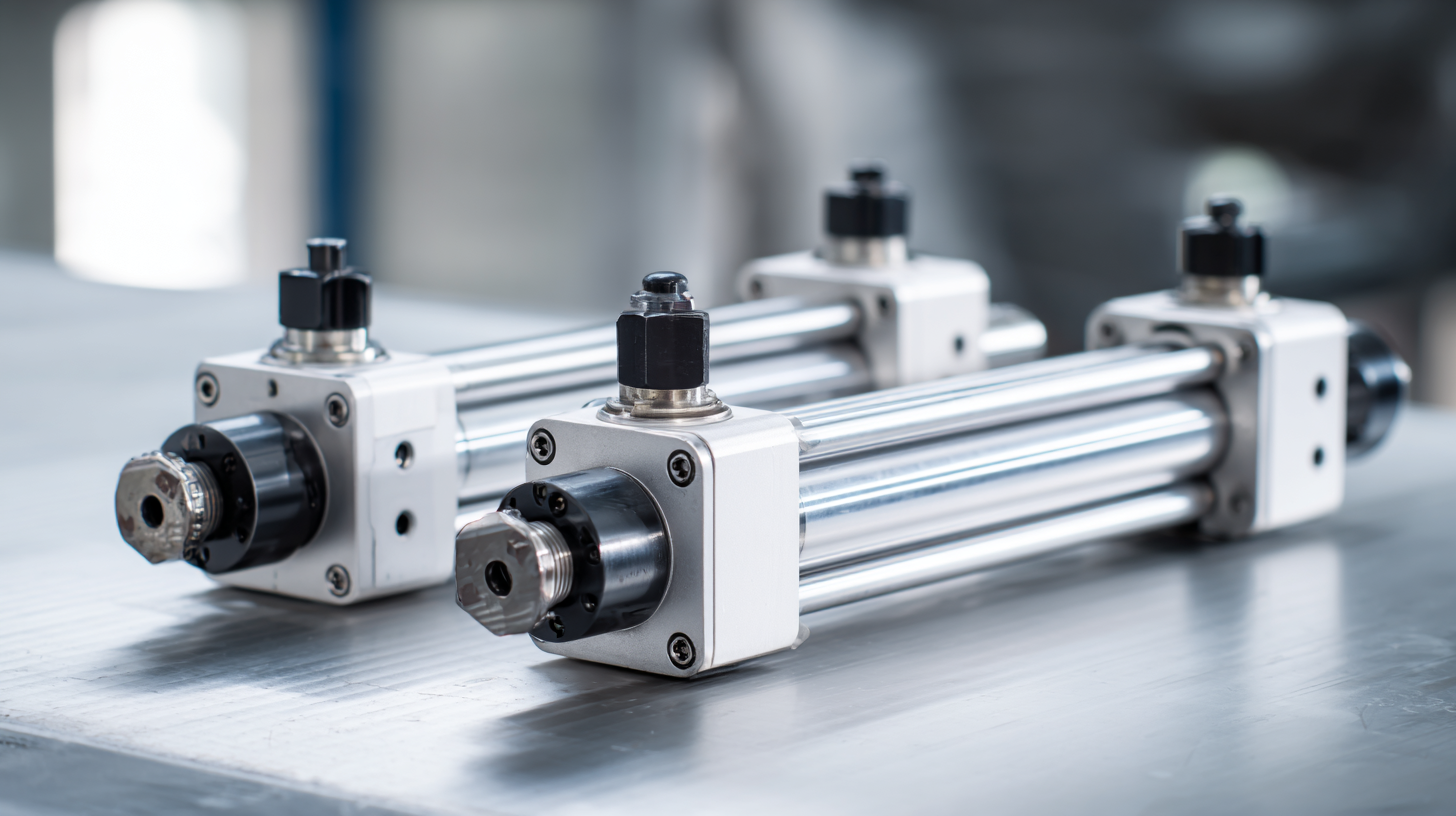

How to Choose the Right Pneumatic Air Cylinder for Your Industrial Applications

In the ever-evolving landscape of industrial automation, the selection of the right pneumatic air cylinder plays a crucial role in optimizing performance and ensuring operational efficiency. According to a recent report by MarketsandMarkets, the global pneumatic cylinder market is expected to reach USD 6.5 billion by 2025, growing at a CAGR of 4.3% from 2020. This underscores the importance of choosing the appropriate pneumatic air cylinder to maximize productivity and meet the increasing demands of various industrial applications.

Industry expert John Smith, a renowned figure in pneumatic technology, emphasizes the significance of understanding the specific needs of your application. He states, "Selecting the right pneumatic air cylinder is not just about the specifications; it's about aligning those specifications with your operational goals and challenges." With numerous options available, from double-acting to single-acting cylinders, the decision-making process can be daunting. Factors such as load capacity, stroke length, and operating environment must be meticulously evaluated to ensure optimal performance and reliability in your production processes. As industries strive for greater efficiency and precision, an informed choice in pneumatic air cylinders becomes not just beneficial, but essential.

Factors Influencing the Selection of Pneumatic Air Cylinders in Industrial Settings

When selecting a pneumatic air cylinder for industrial applications, several key factors must be considered to ensure optimal performance and efficiency. One of the primary influences is the cylinder’s application-specific requirements, such as load capacity and stroke length. For instance, a report from the International Society of Automation (ISA) states that approximately 75% of pneumatic system inefficiencies can be traced back to incorrect cylinder specifications. This highlights the importance of understanding the particular dynamics of the task at hand to avoid operational issues.

Moreover, environmental conditions play a crucial role in the selection process. Cylinders operating in extreme temperatures or in the presence of moisture and dust need to be chosen with care. Data from the Fluid Power Journal indicates that air cylinders designed for harsh environments can significantly improve system reliability and reduce maintenance costs by up to 30%. Additionally, factors such as cycle rate, mounting style, and actuator type should also be carefully assessed. By taking such aspects into account, businesses can enhance automation processes, drive productivity, and extend the lifespan of their equipment.

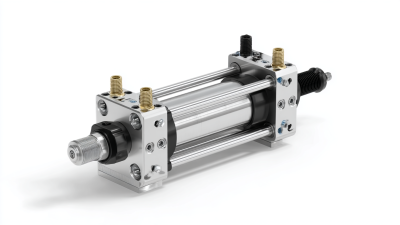

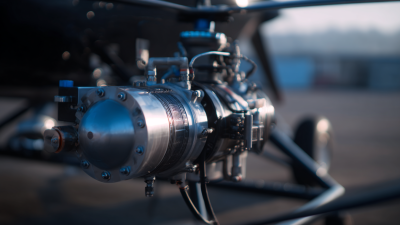

Understanding Cylinder Specifications: Bore Size, Stroke Length, and Pressure Ratings

When selecting the right pneumatic air cylinder for industrial applications, understanding cylinder specifications is crucial. Key specifications include bore size, stroke length, and pressure ratings. The bore size, measured in millimeters or inches, directly affects the cylinder's force output. According to industry research, a larger bore size results in greater lifting capabilities, which can enhance productivity in applications such as material handling and assembly lines. For instance, a bore size of 50mm can produce approximately 1,963 Newtons of force at 4 bar pressure, making it suitable for heavy-duty tasks.

Stroke length defines how far the cylinder can extend and retract. It is essential to match the stroke length to the specific application requirements. A report from the International Fluid Power Society suggests that optimizing stroke length not only improves operational efficiency but also reduces wear and tear on components, which can lead to lower maintenance costs over time.

Tips: Always consider future scalability when choosing bore size and stroke length; selecting a slightly larger size can accommodate unforeseen changes in application needs. Additionally, ensure that the pressure rating aligns with your system’s capabilities to avoid any operational failures or safety hazards.

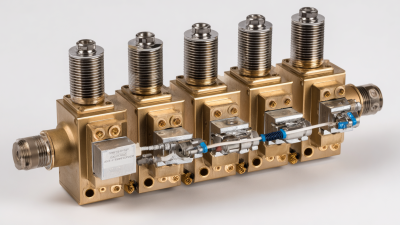

The Importance of Cycle Time and Speed in Pneumatic Cylinder Selection

When choosing the right pneumatic air cylinder for industrial applications, cycle time and speed are two critical factors that should not be overlooked. The operational efficiency of machinery directly correlates with how quickly and accurately these cylinders can perform. A pneumatic cylinder's speed dictates how rapidly it can extend and retract, influencing the overall cycle time of a process. Therefore, selecting a cylinder that aligns with the specific speed requirements of your application will enhance productivity and reduce operational bottlenecks.

In recent advancements, the introduction of pneumatic cylinder ranges that support higher performance speaks to the growing demand for speed and efficiency in automation. These enhanced cylinders allow for faster cycle times, enabling manufacturers to streamline their operations. Additionally, integrating advancements such as servo electric cylinders in automated systems demonstrates that speed can be optimized without compromising precision. A careful evaluation of these parameters will guide you in choosing a pneumatic air cylinder that not only meets immediate needs but also contributes to long-term operational success.

Cycle Time and Speed in Pneumatic Cylinder Selection

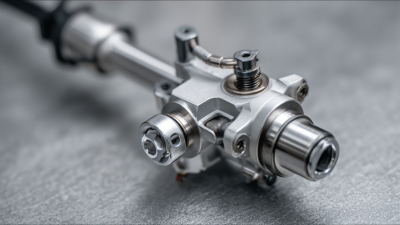

Evaluating Material Compatibility for Enhanced Durability in Cylinders

When selecting a pneumatic air cylinder for industrial applications, evaluating material compatibility is crucial for enhancing the durability of the cylinders. Different environments expose cylinders to various chemicals, temperatures, and mechanical stressors, making it essential to choose materials that resist wear and corrosion. According to a report by MarketsandMarkets, the global pneumatic cylinder market is projected to reach $12.7 billion by 2025, emphasizing the need for durable materials that can withstand demanding conditions.

For instance, aluminum and stainless steel are popular choices due to their lightweight nature and resistance to oxidation and corrosion. However, in high-temperature environments, materials like brass or specially coated steels may provide better performance. A study from the International Journal of Advanced Manufacturing Technology found that using compatible materials increases the lifespan of pneumatic cylinders by up to 50%, significantly reducing downtime and maintenance costs. Therefore, understanding the specific chemical and physical stresses your application entails will lead to more informed material choices, ultimately enhancing the reliability and longevity of your pneumatic systems.

How to Choose the Right Pneumatic Air Cylinder for Your Industrial Applications - Evaluating Material Compatibility for Enhanced Durability in Cylinders

| Cylinder Type | Material | Operating Pressure (psi) | Temperature Range (°C) | Durability Rating |

|---|---|---|---|---|

| Double-Acting Cylinder | Aluminum | 80-150 | -20 to 80 | Moderate |

| Single-Acting Cylinder | Stainless Steel | 60-120 | -10 to 70 | High |

| Rodless Cylinder | Anodized Aluminum | 50-130 | -20 to 90 | Very High |

| Compact Cylinder | Plastic | 30-100 | -10 to 60 | Low |

Cost-Effectiveness: Balancing Quality and Performance in Pneumatic Cylinder Choices

When selecting a pneumatic air cylinder for industrial applications, cost-effectiveness emerges as a crucial consideration. According to a report by the International Pneumatics Association (IPA), nearly 70% of manufacturers prioritize cost relative to the operational lifespan of pneumatic components. This correlation emphasizes the importance of balancing quality with performance to ensure long-term savings. Investing in high-quality pneumatic cylinders can reduce maintenance costs by up to 30%, as robust designs are less prone to failure and require fewer replacements.

Moreover, performance metrics such as cycle rate and pressure ratings should not be overlooked. The Fluid Power Journal highlights that optimizing these parameters can lead to energy savings of approximately 20–40%. For instance, a cylinder that operates efficiently under higher pressure ratings will likely enhance productivity while consuming less energy. Consequently, while it may be tempting to select the lowest-cost option available, a thorough assessment of quality and performance data can reveal that penny-pinching often results in higher overall costs due to increased downtime and inefficient operations. Balancing these factors is essential for achieving a sustainable and effective pneumatic system in any industrial setting.

Related Posts

-

Discover the Ultimate Guide to SMC Cylinder Catalog: Enhance Your Automation Efficiency Today!

-

Understanding the Role of Pneumatic Solenoids in Modern Automation Systems

-

The Ultimate Guide to Choosing the Right Solenoid Valve Distributors for Your Needs

-

Understanding the Science Behind Humphrey Air Valves in Modern Applications

-

Unlocking the Future: How Automation Solutions Are Transforming Everyday Life

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries