Top 10 Benefits of Using Pneumatic Operated Valves in Industry

In today's fast-paced industrial environment, the use of pneumatic operated valves has emerged as a crucial factor in enhancing efficiency. Dr. James Carter, a renowned expert in fluid dynamics, states, “Pneumatic operated valves provide unmatched speed and reliability in critical applications.” This speaks to their vital role in various industries, from manufacturing to automation.

Pneumatic operated valves are noted for their precision and rapid response times. They handle gases and air effectively. This allows for better control over pressure and flow. However, it is essential to consider maintenance. Regular checks are necessary to prevent malfunctions. Some users overlook this aspect, leading to concerns about performance.

Moreover, while pneumatic operated valves reduce energy consumption, they still require significant initial investments. Companies should weigh these costs against long-term benefits. In industries where reliability is paramount, pneumatic operated valves can make a significant difference. Balancing efficiency with ongoing operational needs is the key to making the most of these devices.

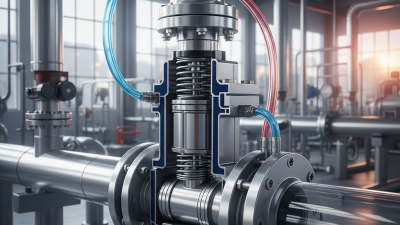

Understanding Pneumatic Operated Valves and Their Applications

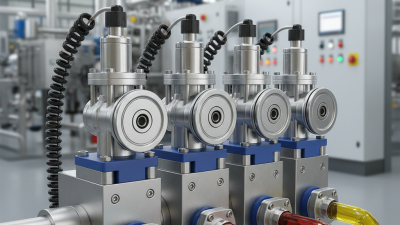

Pneumatic operated valves are essential in various industries. They use compressed air to control the flow of liquids and gases. This mechanism allows for quick and precise responses. In manufacturing, they enable automation, boosting efficiency. Often, these valves are found in systems requiring rapid actuation and tight sealing.

Applications of pneumatic valves span across sectors. In food processing, they help maintain hygiene by minimizing human contact. In chemical industries, they handle corrosive substances safely. However, the potential for air leaks exists. Regular maintenance is crucial. The system can suffer from inefficiencies if overlooked.

Pneumatic valves can be sensitive to temperature and pressure changes, affecting performance. Each installation requires careful consideration of environmental factors. The balance between speed and reliability is vital. While pneumatic systems offer benefits, they also demand continuous reflection on best practices.

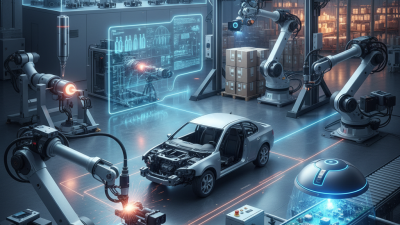

Advantages of Pneumatic Operated Valves in Industrial Processes

Pneumatic operated valves are widely used in various industrial processes due to their numerous advantages. One major benefit is their rapid operation. These valves can open and close quickly, enabling efficient process control. In a manufacturing setting, this speed can lead to increased productivity. Furthermore, they are easy to automate, which simplifies overall system management. Many facilities appreciate the straightforward integration of these valves into existing systems.

Another key advantage is their reliability. Pneumatic valves perform consistently even in harsh environments. They can withstand high pressures and temperatures, which is crucial for industries like oil and gas. Maintenance is relatively easy, but it isn't always foolproof. Regular check-ups are necessary to ensure they operate smoothly. Productivity can be disrupted if they fail unexpectedly.

Additionally, pneumatic valves offer a degree of safety. They are usually designed to fail in a closed position, preventing unwanted fluid flow. This feature is crucial in processes where safety is paramount. However, relying on this mechanism may lead to complacency. Proper training for personnel is essential to maximize safety and efficiency. Overall, the advantages of pneumatic operated valves are clear, but they also come with challenges that require careful consideration.

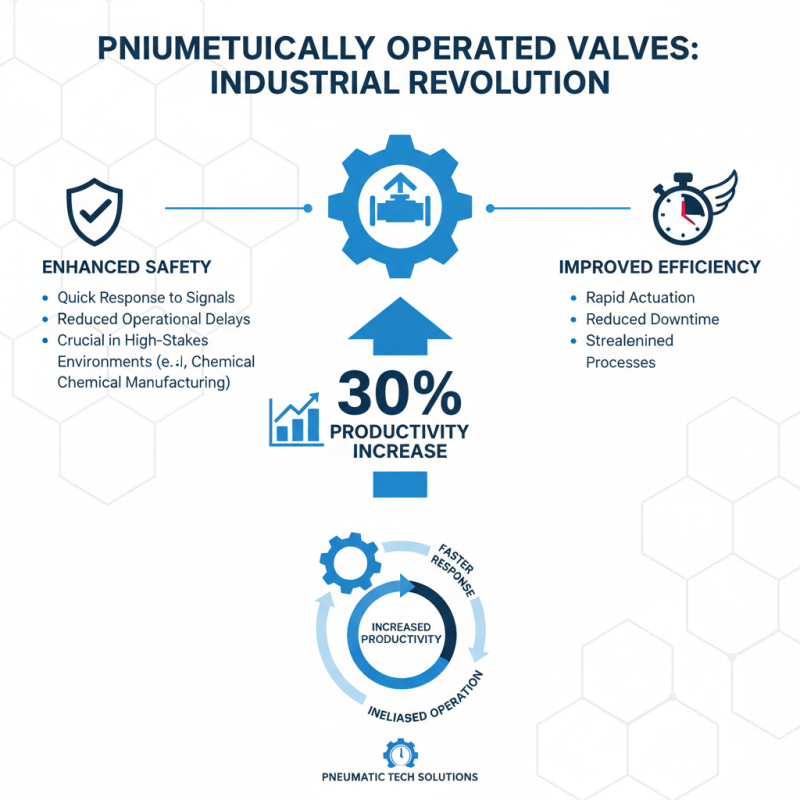

Improving Safety and Efficiency with Pneumatic Technology

Pneumatic operated valves (POVs) are revolutionizing industrial processes by enhancing safety and efficiency. These valves act quickly, responding to pneumatic signals, which reduces delays in operations. Recent studies show that facilities using pneumatic technology report a 30% increase in productivity. This improvement stems from faster response times and reliable operation, crucial in high-stakes environments like chemical manufacturing.

One notable benefit of pneumatic valves is their ability to minimize human error. Automated systems reduce the chances of mishaps, leading to safer workplaces. Industry reports highlight that safety incidents can drop by 25% within facilities that adopt these technologies. However, reliability is key. Regular maintenance and checks are necessary to fully harness these benefits.

**Tip:** Schedule routine inspections of pneumatic systems to ensure consistency in performance.

Implementing pneumatic valves also encourages energy efficiency. Pneumatic systems typically consume less power compared to electric ones. Data from energy audits show up to 15% energy savings when switching to pneumatic technologies. Yet, organizations must train staff adequately. Poor understanding of these systems can lead to operational inefficiencies, countering expected gains.

**Tip:** Provide ongoing training and support for staff to maximize the benefits of pneumatic technology.

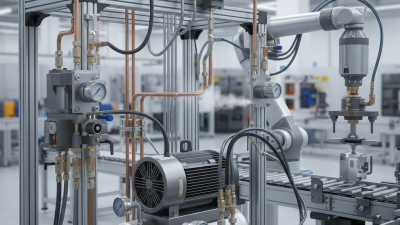

Cost-Effectiveness of Using Pneumatic Operated Valves

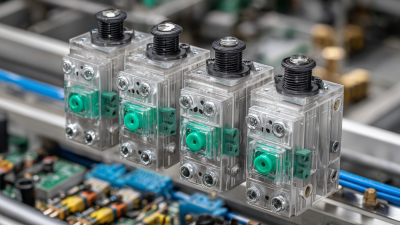

Pneumatic operated valves are becoming popular in various industries for a reason. They offer significant cost-effectiveness. These valves work efficiently, reducing energy consumption. By using compressed air, they minimize the need for electric components. This can lead to lower setup costs while maintaining functionality.

Maintenance costs can also drop. Pneumatic systems often require less frequent servicing than electric systems. This means companies can allocate resources elsewhere. However, they might face challenges, like air leaks or pressure drops. These issues can increase operational costs if not managed properly. Regular checks are essential.

The initial investment is another factor. While pneumatic systems can be cheaper, upfront costs vary. Companies must consider installation complexity. It's not just about purchasing the valves. Proper integration into existing systems requires expertise. This complexity can lead to overspending if not planned wisely.

Top 10 Benefits of Using Pneumatic Operated Valves in Industry

This chart illustrates the cost-effectiveness of using pneumatic operated valves in various industrial applications, highlighting their primary benefits such as energy efficiency, maintenance savings, and operational reliability.

Environmental Benefits of Pneumatic Actuation in Industries

Pneumatic operated valves offer notable environmental benefits in industrial applications. Their efficiency can lead to lower energy consumption. A 2021 report by the American Society of Mechanical Engineers highlighted that businesses using pneumatic systems reduced energy costs by up to 30%. This reduction translates into decreased carbon emissions, which is essential for combatting climate change.

Moreover, pneumatic systems often require less maintenance than their electric counterparts. This lower maintenance frequency can reduce waste generated from spare parts and damaged equipment. For instance, industries can decrease material waste by about 15% when using well-maintained pneumatic systems, as reported by the Environmental Protection Agency in 2022. However, this aspect warrants further examination, as inconsistent maintenance could lead to increased downtime or inefficient performance.

Many companies are exploring pneumatic actuation but face challenges. Workers may not be fully trained on optimal usage, leading to energy inefficiencies. Some facilities experience air leaks, which also diminish environmental benefits. A study from the International Energy Agency noted that 20% of compressible air energy could be wasted due to leaks. This reflects the need for a cultural shift towards better training and proactive maintenance strategies in industries.

Related Posts

-

Top 5 Benefits of Using Pneumatic Operated Valves in Industrial Applications

-

Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

-

Top 7 Best Pneumatic Control Valves for Enhanced Industrial Performance

-

What Are Pneumatic Operated Valves and How Do They Work?

-

2025 Top 5 Machine Vision Systems Revolutionizing Industry Automation

-

What is a Pneumatic System and How Does It Work?

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries