Top 5 Benefits of Using Pneumatic Operated Valves in Industrial Applications

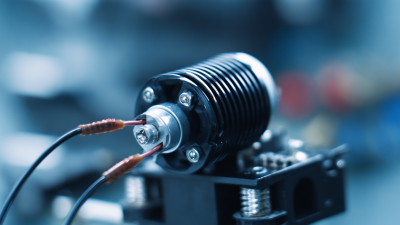

In the realm of industrial applications, the use of pneumatic operated valves has become increasingly prominent due to their remarkable efficiency and reliability. As noted by Dr. Jane Smith, a leading expert in fluid control technologies, "Pneumatic operated valves not only enhance the operational efficacy of systems, but they also offer unparalleled safety and precision in various industrial environments." This sentiment highlights the growing recognition of pneumatic operated valves as essential components in automating processes and controlling fluid dynamics.

The benefits of utilizing pneumatic operated valves extend beyond mere functionality. They encompass aspects such as reduced operational downtime, increased safety, and improved system flexibility. These advantages make them a preferred choice for industries ranging from manufacturing to energy production. Moreover, their resilience and versatility in different working conditions contribute significantly to optimizing performance, thereby underscoring the vital role they play in modern industrial setups. In this discussion, we will delve into the top five benefits of using pneumatic operated valves, illuminating their crucial impact on enhancing industrial applications.

Overview of Pneumatic Operated Valves in Industrial Settings

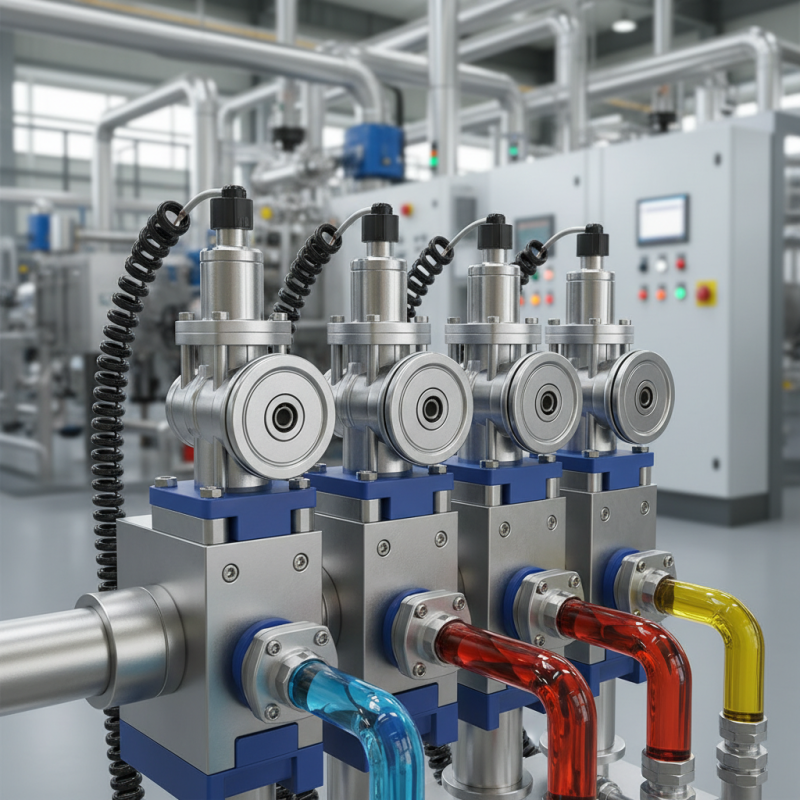

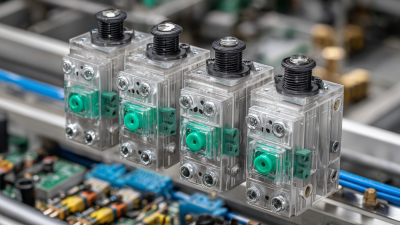

Pneumatic operated valves have become integral components in various industrial applications due to their efficiency and reliability. These valves utilize compressed air to control fluid flow, offering a level of precision that mechanical systems struggle to match. According to a recent report by the International Society of Automation, over 30% of industrial facilities have transitioned to using pneumatic actuators, primarily due to their capability to operate at higher speeds and with greater responsiveness than traditional systems. This shift highlights the trend toward automation and efficiency in the industrial sector.

In terms of applications, pneumatic operated valves are widely used in manufacturing, chemical processing, and water treatment facilities. A study by Research and Markets suggests that the global pneumatic valve market is expected to grow alongside the growing automation in the industries, projected to reach approximately $7 billion by 2025, at a CAGR of 5.2%. This growth is largely driven by the increasing need for reliable and efficient fluid management systems, making pneumatic operated valves critical for maintaining consistent operations while minimizing downtime. The ability to handle high cycle rates without significant wear and tear further solidifies their importance in high-demand environments.

Increased Efficiency and Productivity through Pneumatic Systems

Pneumatic operated valves are increasingly becoming essential in industrial applications due to their capacity to enhance efficiency and productivity. According to a report by MarketsandMarkets, the global pneumatic valve market is projected to grow from $3.2 billion in 2020 to $4.4 billion by 2025, highlighting a growing recognition of their operational advantages. One of the primary reasons for this growth is the increased speed and accuracy these systems provide. Pneumatic valves can actuate rapidly, reducing response times in various processes, which allows for decreased downtime and maximized throughput in manufacturing settings.

In addition to speed, the integration of pneumatic systems leads to significant energy savings. A study conducted by the U.S. Department of Energy found that pneumatic systems can realize efficiency improvements of up to 30% when properly maintained and optimized. This efficiency translates not only into cost savings on energy but also into a smaller environmental footprint. These systems enable precise control over fluid flow and pressure, which can optimize production rates and enhance overall performance. The capability to streamline operations through such reliability ensures that industries can meet increasing demands with consistent quality and reduced errors.

Top 5 Benefits of Using Pneumatic Operated Valves in Industrial Applications

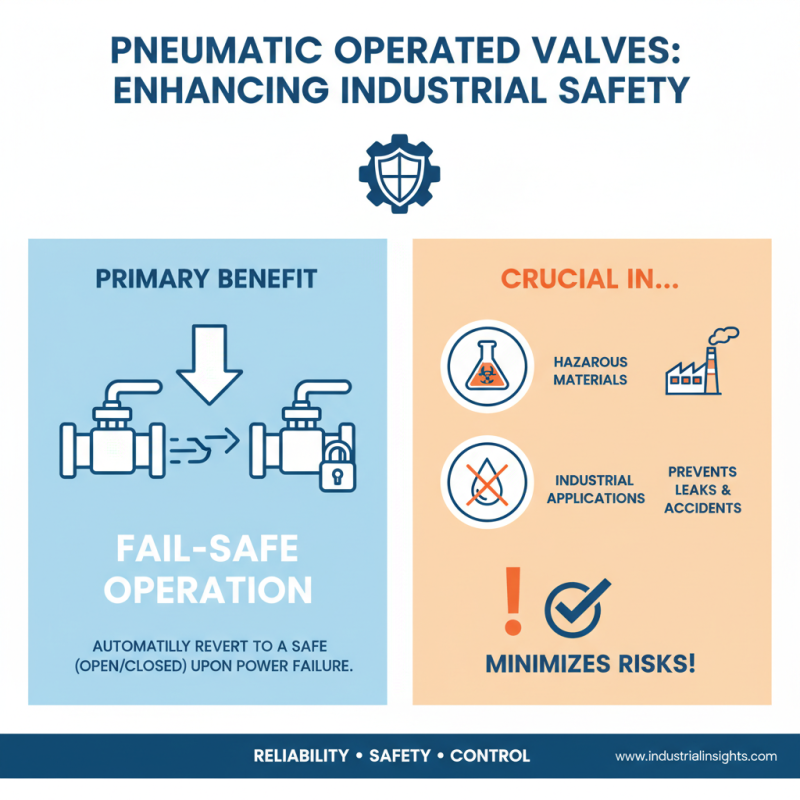

Enhanced Safety Features of Pneumatic Operated Valves

Pneumatic operated valves are pivotal in enhancing safety features across various industrial applications. One of the primary benefits of these valves is their fail-safe operation. In the event of a power failure, pneumatic systems can revert to a predetermined safe position, either fully open or closed, minimizing the risks of leaks or accidents. This characteristic is particularly crucial in industries handling hazardous materials, where even a minor leak could result in catastrophic consequences.

Moreover, pneumatic operated valves are less prone to mechanical failure due to their simpler design. With fewer moving parts compared to their electromechanical counterparts, these valves reduce the potential for breakdowns. Their quick response times contribute to improved overall safety; any irregularities in system performance can be detected and addressed swiftly. Additionally, the use of compressed air as a power source eliminates the risk of electrical fires and sparks, making these valves an ideal choice for explosive environments. The integration of pneumatic operated valves not only promotes operational efficiency but also significantly bolsters safety measures within industrial settings.

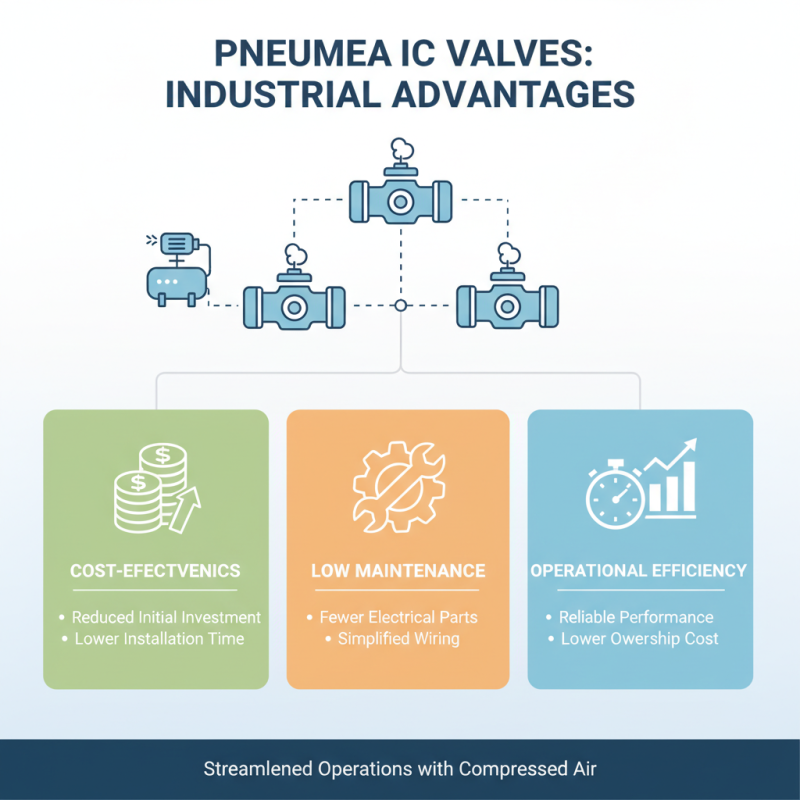

Cost-Effectiveness and Maintenance Benefits of Pneumatic Valves

Pneumatic valves are increasingly favored in industrial settings due to their significant cost-effectiveness and low maintenance requirements. By utilizing compressed air to create motion, these valves streamline operations, reducing the need for complex electrical components and extensive wiring. This simplicity not only cuts initial investment costs but also minimizes installation time, making pneumatic systems an economical choice for many industries. The operational efficiency gained from pneumatic valves contributes to a lower overall cost of ownership, as they can handle various tasks with reliable performance.

In addition to their cost benefits, pneumatic valves are designed for durability and ease of maintenance. Unlike their electric counterparts, which may require frequent troubleshooting, pneumatic valves tend to have fewer failure points, leading to a reduced likelihood of downtime. Regular maintenance on pneumatic systems can be accomplished quickly, often requiring just routine inspections and occasional part replacements. This inherent reliability means that operations can continue uninterrupted, further enhancing productivity and reducing operational costs over time. Overall, the economic advantages and practical maintenance of pneumatic valves make them an ideal choice for industrial applications.

Applications of Pneumatic Operated Valves in Various Industries

Pneumatic operated valves have gained significant traction across various industrial sectors due to their efficiency and reliability. The versatility of these valves is evident in their widespread applications, ranging from oil and gas to pharmaceuticals. In the oil and gas industry, pneumatic valves are pivotal in controlling the flow of fluids with precision. According to a report from the International Energy Agency, the demand for automation in the oil and gas sector is projected to grow by 6% annually, emphasizing the need for reliable control systems such as pneumatic valves.

Moreover, the pharmaceutical industry utilizes pneumatic operated valves to maintain stringent hygiene and control environments necessary for manufacturing. A study by the Pharmaceutical Research and Manufacturers of America indicates that 40% of pharmaceutical manufacturing facilities are expected to adopt advanced automation technologies in the coming years. Such advancements facilitate better compliance with safety regulations and enhance product quality, showcasing how pneumatic valves play a critical role in regulatory adherence.

Related Posts

-

Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

-

Top 7 Best Pneumatic Control Valves for Enhanced Industrial Performance

-

How to Navigate the SMC Cylinder Catalog for Efficient Selection and Use

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Unlocking the Magic of Pneumatic Solenoids: A Deep Dive into Their Applications and Innovations

-

How to Choose the Right Norgren Valves for Your Industrial Applications 2025

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries