2026 Best SMC Cylinder Catalog Overview and Recommendations?

In the world of automation and pneumatics, the "SMC cylinder catalog" stands as a vital resource for engineers and designers. Experts like Dr. John T. Miller emphasize its importance, stating, "The SMC cylinder catalog is essential for efficient system design." It offers a comprehensive overview of product options, specifications, and applications.

Navigating this catalog can be daunting. With so many options available, it's easy to feel overwhelmed. Yet, making the right choice is crucial for operational success. Familiarity with the catalog's layout is key; users need to know where to find precise information. Every detail matters. A wrong selection can lead to efficiency losses or increased costs.

The 2026 edition of the SMC cylinder catalog has introduced various innovations. However, some users may find it less intuitive than previous versions. There are still gaps that warrant scrutiny. New products often require thorough testing to assess their real-world performance. Understanding the real implications of these changes is essential for any professional relying on this critical resource.

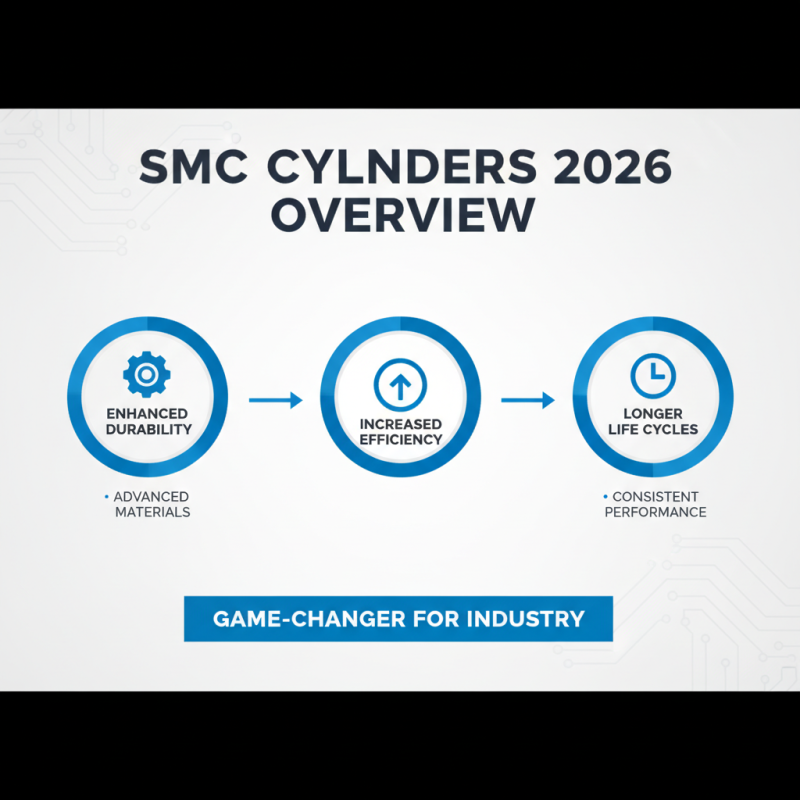

2026 SMC Cylinder Overview: Key Features and Innovations

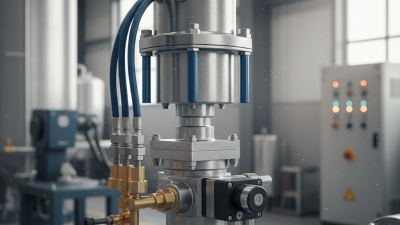

The 2026 overview of SMC cylinders presents several key features that stand out. These cylinders focus on enhanced durability and efficiency. Advanced materials are used to minimize wear and tear. This leads to longer life cycles, which can be a game changer for industries that rely on consistent performance.

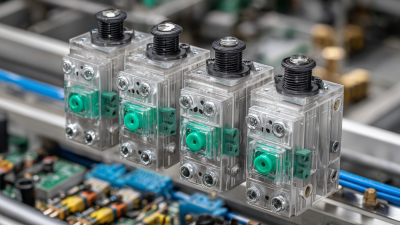

Innovations in design have also been introduced. The new cylinders often exhibit a more compact profile without compromising power. They cater to a variety of applications, from robotics to manufacturing. Understanding the specific needs of each application can lead to better choices. However, not all innovations may suit every environment.

Maintaining a balance between functionality and complexity is crucial. Some designs may seem overly complicated, leading to hesitation. Users should weigh the benefits against potential challenges. Embracing these innovations means embracing the learning curve. Each change presents an opportunity to adapt.

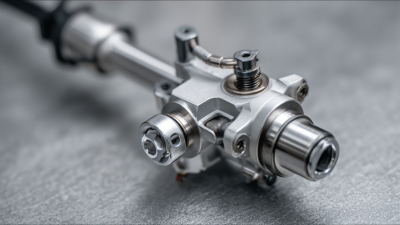

Top SMC Cylinder Models for Enhanced Efficiency in Industrial Applications

In today’s industrial landscape, selecting the right cylinder can elevate operational efficiency. There are various models designed to optimize performance. Enhanced efficiency starts with understanding your specific needs.

One highly regarded type is the compact cylinder. It’s perfect for tight spaces. These cylinders offer high-speed operations and precise control. Another option is the lightweight aluminum cylinder. It's durable yet easy to install. Its versatility makes it suitable for multiple applications.

However, not all cylinders perform equally in every setting. Some may underdeliver under specific conditions, leading to frustration. It's essential to assess each model against your operational demands. Consider factors like load capacity and speed. Sometimes, compromise is unavoidable. The best choice isn’t always the most expensive. Always keep an eye on your real-world requirements. Finding the right balance can significantly affect efficiency.

2026 Best SMC Cylinder Catalog Overview and Recommendations

| Model | Bore Size (mm) | Stroke Length (mm) | Max Pressure (MPa) | Weight (kg) | Application |

|---|---|---|---|---|---|

| C12H | 12 | 100 | 1.0 | 0.2 | Pick & Place |

| C16H | 16 | 150 | 1.0 | 0.3 | Handling |

| C25H | 25 | 200 | 1.5 | 0.7 | Automation |

| C32H | 32 | 250 | 1.5 | 1.1 | Heavy Duty |

| C40B | 40 | 300 | 1.5 | 1.5 | Lifting |

Performance Metrics: Evaluating SMC Cylinders for Optimal Selection

When selecting cylinders, performance metrics play a vital role. Evaluation involves understanding factors like stroke length, load capacity, and operating speed. A 2022 industry report highlights that 30% of failures stem from improper cylinder selection. This data emphasizes the need for careful assessment.

Cylinder efficiency is critical. An ideal choice could save energy by up to 20%. Costs associated with energy waste can add up. A powerful cylinder may seem attractive, but can lead to excess energy consumption. A balance of performance and efficiency is essential.

Tips: Focus on application needs. Understand the environment where the cylinder will operate. Short strokes may require faster response, while long strokes might need higher force. Also, consult metrics from reliable sources to ensure your selection is backed by data. Quality over quantity can guide your decision.

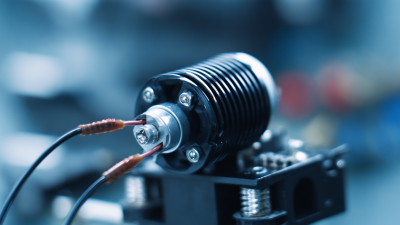

Industry Trends: The Future of Pneumatic Cylinder Technology in 2026

As we look toward 2026, pneumatic cylinder technology is poised for significant advancements. The industry is shifting towards electric solutions, driven by demand for energy efficiency. Reports indicate that electric actuators are projected to capture 30% of the market share by 2026. This is a notable shift from traditional pneumatic systems. Companies are increasingly focusing on reducing energy consumption and maintenance costs.

Innovative materials are also set to play a key role in the future. Lightweight composites may enhance the efficiency and lifespan of cylinders. Industry experts anticipate that the adoption of smart technologies will rise sharply, making cylinders more adaptive and connected. Sensors embedded in cylinders could provide real-time data, allowing for better predictive maintenance.

Despite these advancements, challenges remain. The transition to new technologies can be slow. Not all industries have the budget for cutting-edge solutions. Additionally, there is often a gap in training for workers on new systems. The shift towards automation needs careful planning to avoid operational disruptions. Balancing innovation with practical implementation will be crucial for success by 2026.

Recommendations for Maintenance and Longevity of SMC Cylinders

When it comes to maintaining SMC cylinders, proper care is vital. Regular inspections can significantly enhance cylinder longevity. Look for signs of wear or damage. Any unusual noises during operation? This could indicate a problem.

Tips: Check seals frequently. A worn seal can cause leaks, leading to costly downtime. Use appropriate lubricants. Too much or too little can impact performance.

Cleaning is essential. Dust and debris can accumulate, affecting operation. A gentle wipe with a cloth works wonders. Ensure that all components function smoothly. Misalignment might not seem serious but can lead to bigger issues later.

Remember, monitoring ambient conditions matters too. High temperatures can impact cylinder performance. Avoid exposing cylinders to harsh environments. Reflect on your current maintenance routine. Are you proactive or reactive? Adapting a forward-thinking approach can save resources in the long run.

2026 SMC Cylinder Performance Overview

Related Posts

-

Discover the Ultimate Guide to SMC Cylinder Catalog: Enhance Your Automation Efficiency Today!

-

How to Navigate the SMC Cylinder Catalog for Efficient Selection and Use

-

How to Choose the Right Air Cylinder for Your Application

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

-

What is a Pneumatic Control Valve and How Does It Work?

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries