2026 Best Air Solenoid Options for Efficient Automation Solutions?

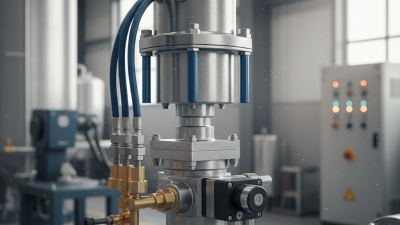

In the quest for automation, the air solenoid stands out as a crucial component. These devices convert electrical energy into mechanical force, making them integral in many applications. Industries rely on air solenoids for reliability and efficiency.

Selecting the best air solenoid can significantly impact automation processes. It’s essential to consider various factors such as size, force, and response time. Some models excel, while others may underperform. Users must weigh options carefully. An air solenoid that works in one application might not suit another. This inconsistency raises questions about compatibility and performance.

In 2026, manufacturers are innovating in this space. New designs promise improved energy efficiency and better performance. Yet, the market can be overwhelming. With choices ranging from basic to advanced, buyers often struggle to make informed decisions. This evolution in technology is exciting, yet it necessitates careful reflection. Choosing the right air solenoid can lead to efficient automation, but poor selections can hinder operations.

Overview of Air Solenoid Technology in Automation Systems

Air solenoids play a vital role in automation systems. They serve as key components in controlling pneumatic actuators and valves. According to a recent industry report from Markets and Markets, the global market for pneumatic actuators is projected to reach $29.47 billion by 2025. This growth reflects the increasing demand for efficient automation solutions across various sectors.

These solenoids convert electrical energy into mechanical movement. In many applications, they can improve response times and enhance reliability. However, not all air solenoids are created equal. Quality can vary significantly among manufacturers. Users often face challenges when it comes to durability and compatibility. In some cases, solenoids may fail under high stress or prolonged use.

Precision is essential. A small error in sizing or installation can lead to performance issues. Reports show that over 20% of failures in automation systems are linked to component selection. This highlights the need for careful evaluation of options. Proper maintenance is equally important. Neglecting routine checks may lead to unexpected downtime. In a fast-paced industry, this can have costly repercussions. Understanding these factors is crucial for achieving optimal efficiency in automation systems.

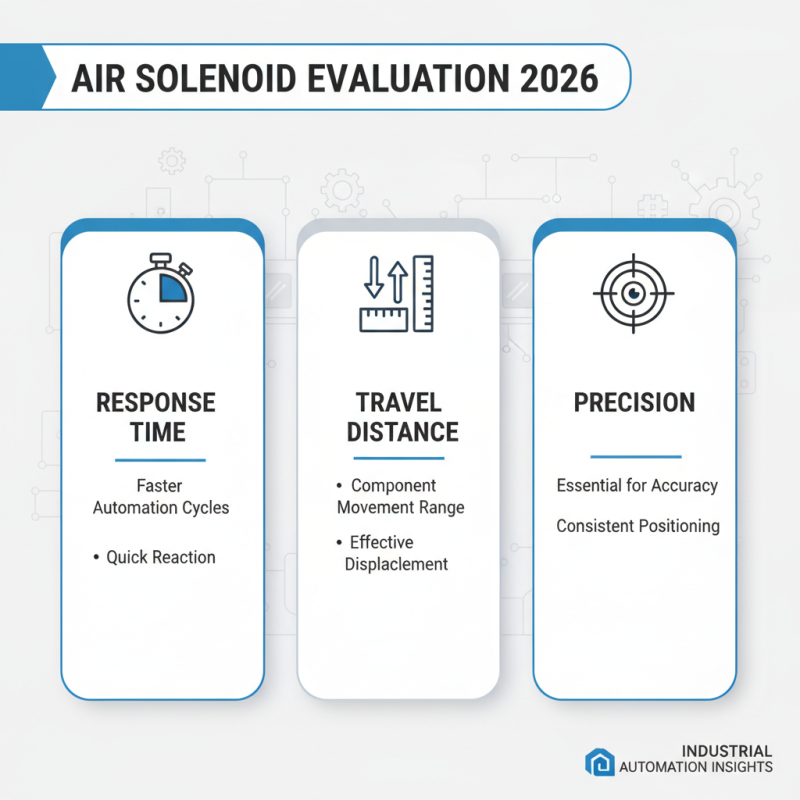

Key Specifications for Evaluating Air Solenoids in 2026

When evaluating air solenoids in 2026, consider key specifications that impact performance. One major factor is the response time. A quick response ensures faster automation cycles. Check the actuator's travel distance. It determines how far the solenoid can move components effectively. In many applications, precision is essential.

Another important specification is pressure handling capabilities. Different tasks require varying levels of air pressure. A solenoid unable to handle the required pressure can lead to failure. Assess power consumption as well. Efficient solenoids minimize energy loss. This aspect is crucial for long-term operational costs.

Additionally, consider the material of the solenoid. Corrosion-resistant materials are vital in industrial settings. They enhance durability and lifespan. However, sometimes, manufacturers might skimp on material quality. Address this by looking at reviews. Performance data can shed light on reliability. Balancing performance with cost often requires careful thought.

Top 2026 Air Solenoid Brands and Their Market Performance

The market for air solenoids is rapidly evolving. According to a recent industry report, the global air solenoid market is projected to reach over $2 billion by 2026. This growth is driven by increasing automation in various sectors, including manufacturing and automotive. However, challenges remain. Quality control and energy efficiency are significant concerns for consumers.

Top brands in the air solenoid industry have been performing well. They focus on innovation and customer satisfaction. Data from 2023 shows that brands that prioritize R&D see a market growth rate of nearly 15%. Despite this, some smaller firms struggle to keep up with larger competitors. They often face issues with production consistency and response times.

End-users are looking for reliable and efficient solenoid valves. Features such as quick response times and low energy consumption are in high demand. A recent survey indicated that over 60% of users reported needing improvements in durability. This highlights an area that some brands must address. Continued investment in technology and quality improvement is vital for long-term success.

Performance Metrics: Comparing Efficiency of Air Solenoids in Automation

When evaluating air solenoids, efficiency is a critical factor. Recent studies show that air solenoids can achieve up to 90% operational efficiency. This metric varies based on design and application. Some models outperform others under specific conditions. It’s essential to analyze the performance in real-world scenarios. A report highlighted that a significant percentage of solenoids fail to meet expected energy consumption standards.

In automation applications, response time and reliability are crucial metrics. Air solenoids with faster actuation times often improve overall system efficiency. Tests showed that solenoids with optimized valve designs can reduce cycle times by 30%. However, these designs may not always be durable. Users reported increased wear in less robust materials. Monitoring conditions and load can reveal these vulnerabilities.

Moreover, the impact of ambient temperature on air solenoid performance should not be overlooked. A 2023 analysis pointed out that solenoids might lose up to 15% efficiency in extreme heat. This fluctuation can lead to inconsistent automation processes. Understanding these performance metrics helps in choosing the best solenoid options for specific applications. It's vital to prioritize efficiency while being aware of potential drawbacks.

Comparison of Air Solenoid Efficiency for Automation (2026)

Future Trends in Air Solenoid Development for Enhanced Automation Solutions

The development of air solenoids is increasingly crucial for automation solutions. Recent reports indicate a projected growth of the automation sector, reaching $200 billion by 2026. This growth reflects rising demand for efficient mechanisms. Manufacturers are focusing on lightweight materials and compact designs. These changes aim to improve performance while reducing overall costs.

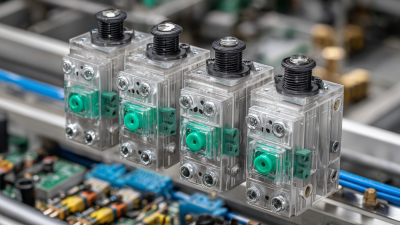

Current trends show a shift toward smart technology integration. Air solenoids equipped with IoT capabilities can enhance system efficiency. However, the challenge lies in maintaining reliability under varying operational conditions. Many innovations require rigorous testing. Testing often exposes weaknesses that need addressing. Not all newly designed solenoids perform as expected in real-world scenarios.

Data reveals that around 30% of automation failures stem from solenoid malfunctions. This statistic highlights the need for ongoing development. Engineers must balance innovation with reliability. As the industry evolves, sustainability becomes essential. Eco-friendly materials in solenoid manufacturing are gaining traction. However, this transition is complex and requires careful planning. The path forward is not without hurdles, but the potential for improved automation is significant.

2026 Best Air Solenoid Options for Efficient Automation Solutions

| Model | Actuation Type | Pressure Range (psi) | Fluid Type | Operating Temperature (°C) | Response Time (ms) |

|---|---|---|---|---|---|

| Model A | Normally Open | 0-150 | Air | -20 to 60 | 50 |

| Model B | Normally Closed | 0-200 | Air | -10 to 70 | 40 |

| Model C | Bi-directional | 0-100 | Air | -20 to 55 | 30 |

| Model D | Double Acting | 0-120 | Air | -10 to 65 | 45 |

| Model E | Electro-Pneumatic | 0-175 | Air | -20 to 60 | 35 |

Related Posts

-

Unlocking the Power of Air Solenoids: A Comprehensive Guide for Engineers and Developers

-

Top 10 Tips for Choosing the Right Air Solenoid for Your Project

-

10 Essential Tips for Choosing the Right Air Solenoid for Your Needs

-

Top 10 Pneumatic Solenoid Valve Choices for Enhanced Automation Efficiency

-

What is a Pneumatic Control Valve and How Does It Work?

-

How to Choose the Right Pneumatic Air Cylinder for Your Application

Get in Touch

570 Alden Road Unit #10, Markham Ontario Canada, L3R 8N5

Quick Links

Featured Products

Industries